sales06@switek.biz

+86 186 5927 5869

sales06@switek.biz

+86 186 5927 5869

| Description | Unité | Valeur |

|---|---|---|

| UNITÉ D'INJECTION | ||

| Volume de tir | cm3 | 1619 |

| Poids du tir | g | 1473 |

| Vitesse de tir | mm/s | 563 |

| Diamètre de la vis | mm | 80 |

| Pression d'injection | MPa | 120 |

| Rapport L:D de vis | -- | 17.5 |

| UNITÉ DE SERRAGE | ||

| Force de serrage | kN | 5500 |

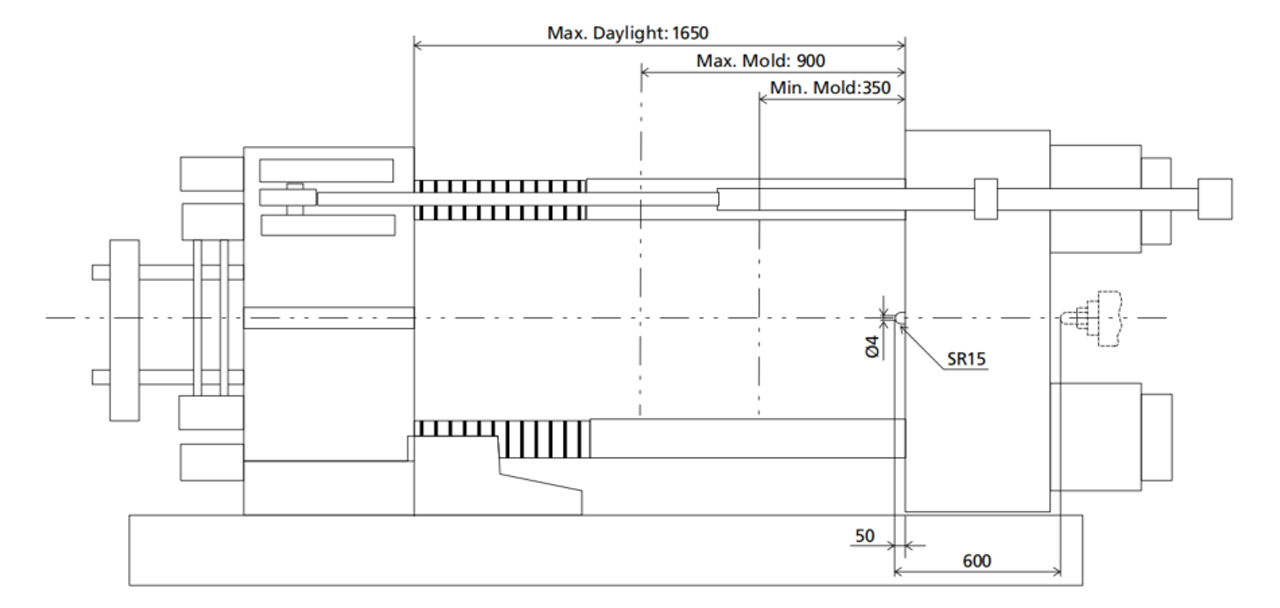

| Coup d'ouverture | mm | 1300 |

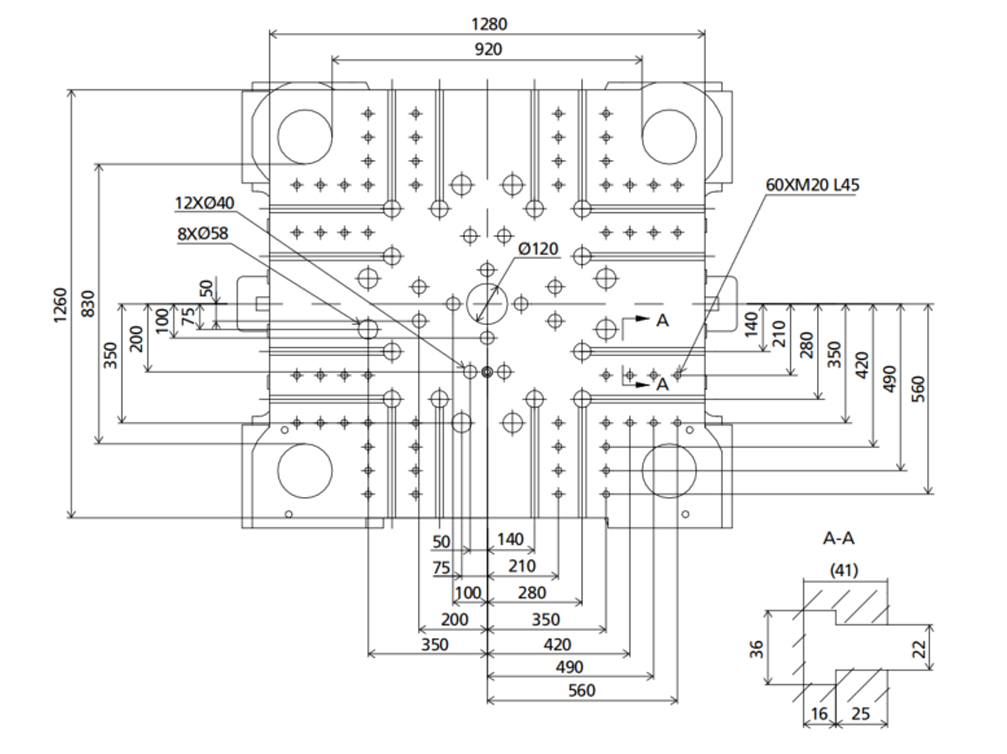

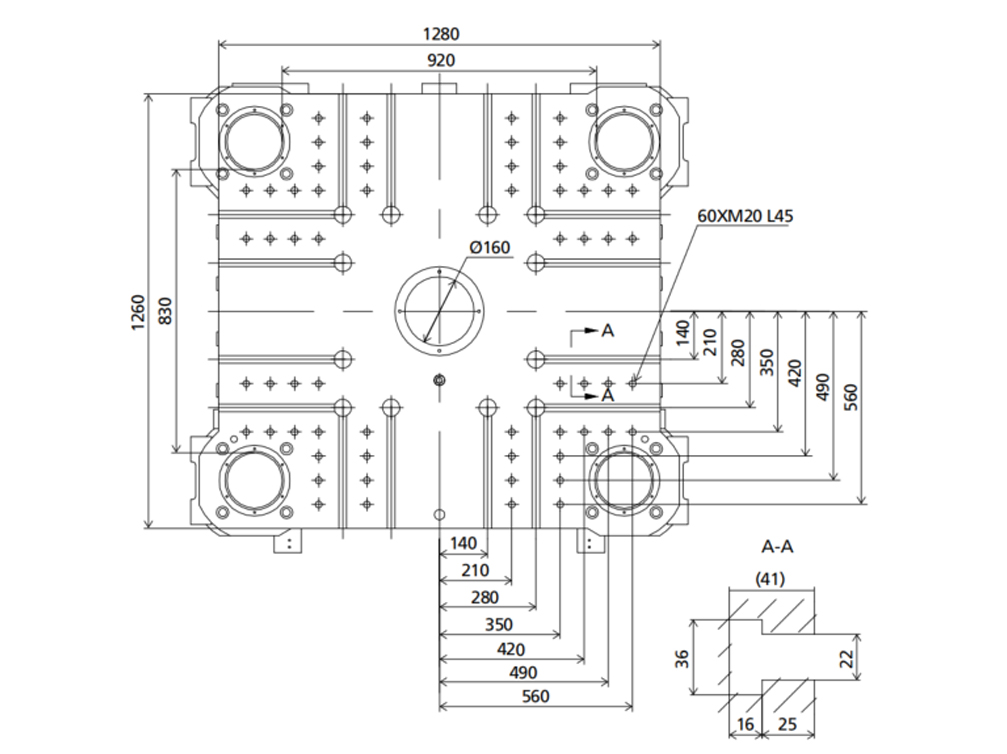

| Espace entre les barres de liaison | mm x mm | 920 x 830 |

| Épaisseur du moule(min) | mm | 350 |

| Épaisseur du moule(max) | mm | 850 |

| Course d'éjection hydraulique | mm | 250 |

| Force d'éjection hydraulique | kN | 110 |

| UNITÉ DE PUISSANCE | ||

| Moteur de pompe | kW | 45 |

| Capacité de chauffage | kW | 33 |

| GÉNÉRAL | ||

| Capacité du réservoir d'huile | L | 450 |

Clamping Unit

Platen Dimensions

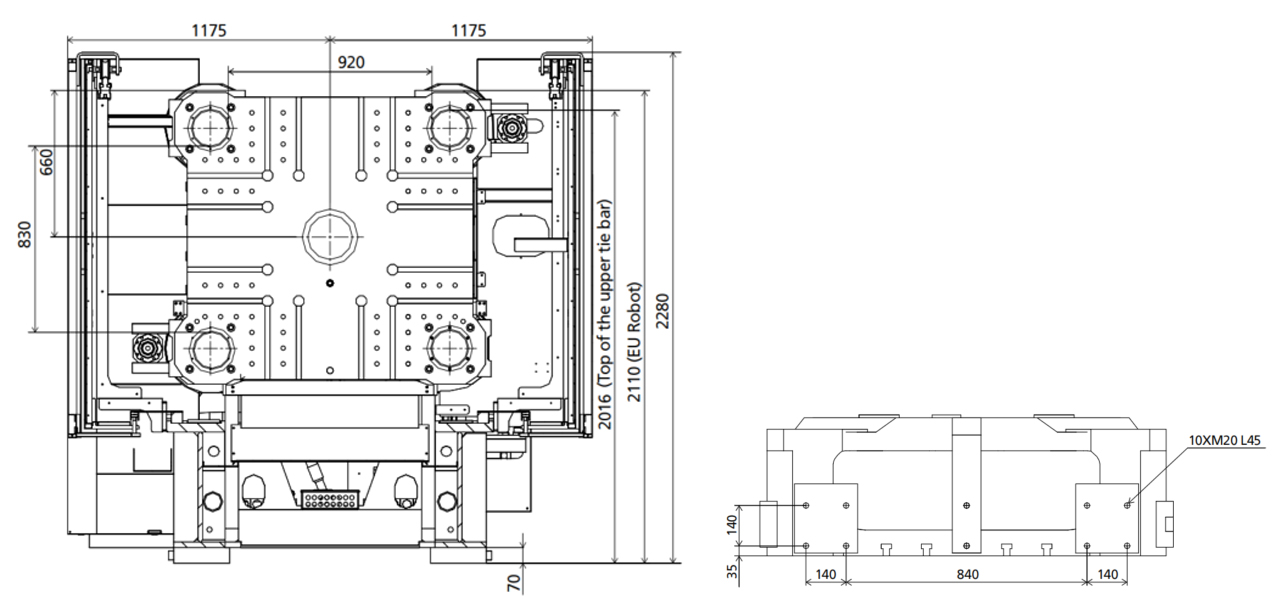

Robot

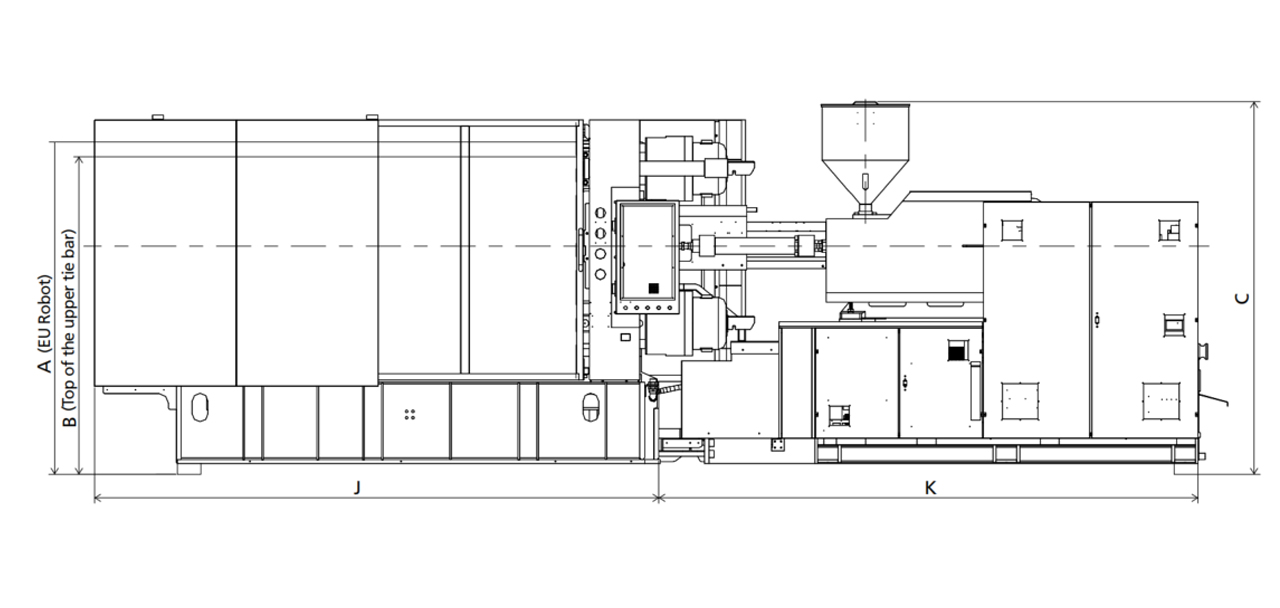

Front View

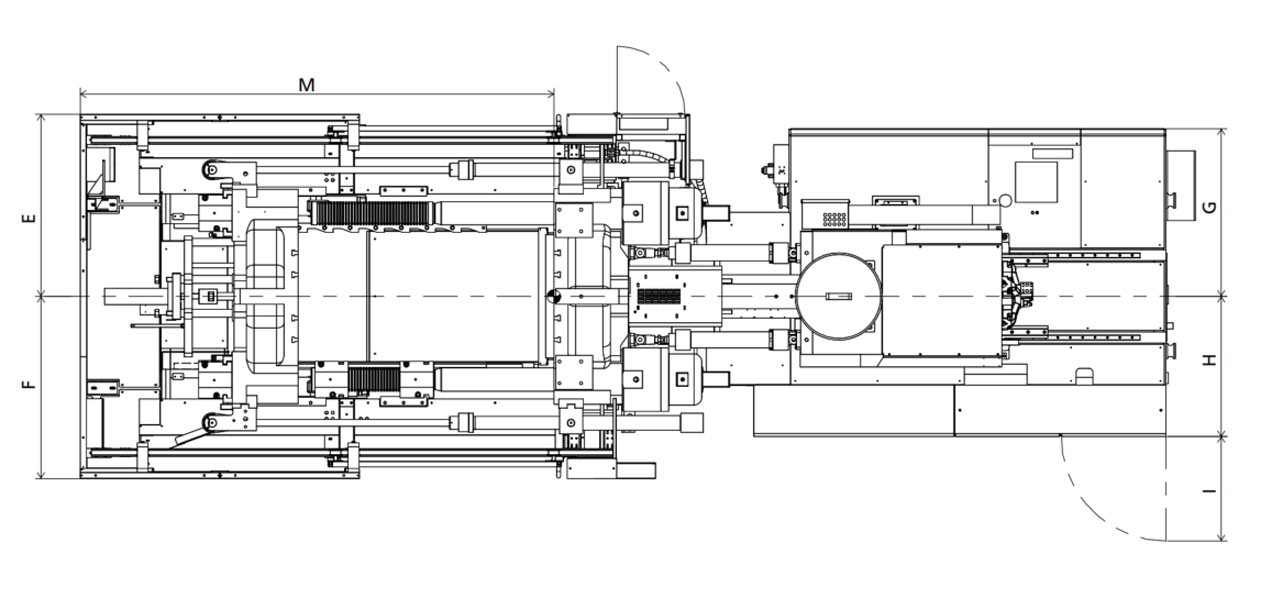

Top View

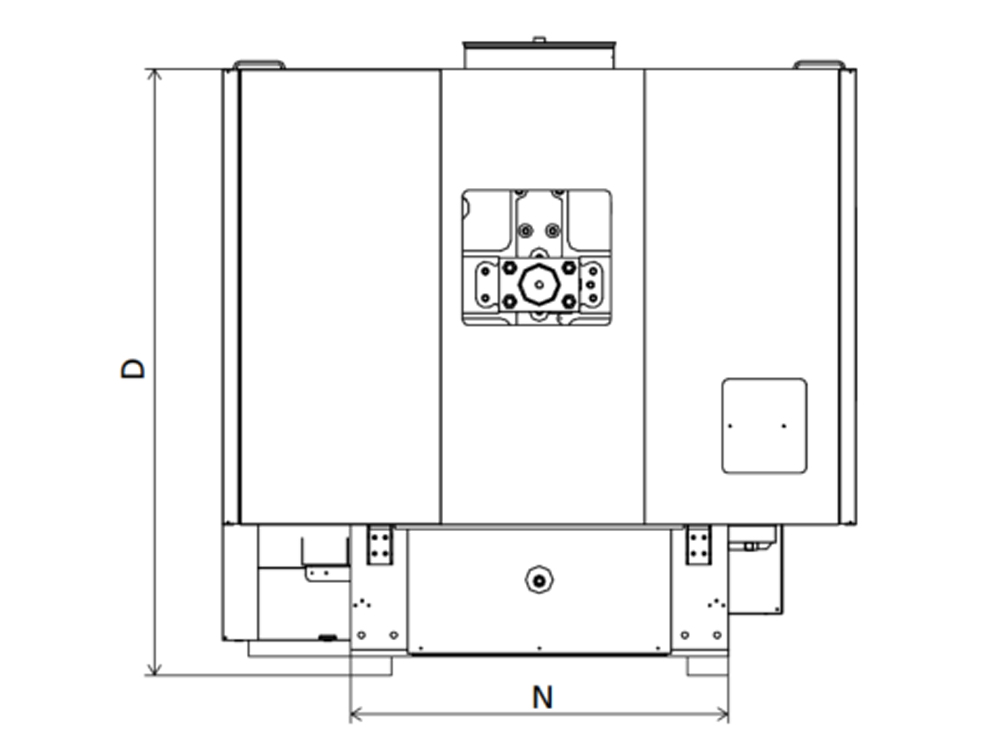

Side View

| # | Value |

|---|---|

| A | 2110 mm |

| B | 2016 mm |

| C | 2327 mm |

| D | 2250 mm |

| E | 1175 mm |

| F | 1175 |

| G | 1082 mm |

| H | 903 mm |

| I | 675 mm |

| J | 3581 mm |

| K | 3705 mm |

| M | 3056 mm |

| N | 1400 |

Will Hybrid An Ideal Injection Molding Machine for IML Project?

Hybrid injection molding machine, a combination of the all electric injection molding machine and the hydraulic injection molding machine, it's no doubt one of the best injection molding machine for your IML project. A hybrid injection molding machine will have the precision of plastic injection also the much lower cost against the all electric injection molding machine.

One of the best buy hybrid injection molding machine made in China is the LDY series of hybrid injection molding machine made by Haida, one of the injection molding machine manufacturer founded in 1992 and is famous for the reliability of the injection molding machines. The LDY series of hybrid injection molding machine is their key products for thin-wall container production markets with a clamping force ranging from 100~420T.

For your IML project, the best IML robot to match Haida LDY series hybrid injection molding machine would be SWITEK SW8 Series IML robot, with control systems by European system provider SigmaTek, the cycle time of SW8 series of IML robot can reach 2.0s for the IML production of small size thin-wall containers or lids. It's one of the fastest IML robot made in China.

Actualités sur l'automatisation de l'injection à chaud

E-mail: sales@switek.biz

Contacter le blogueur

sales06@switek.biz

+86 186 5927 5869

DongGuan, GuangDong, China