sales06@switek.biz

+86 186 5927 5869

sales06@switek.biz

+86 186 5927 5869

| Description | Unité | Valeur |

|---|---|---|

| UNITÉ D'INJECTION | ||

| Volume de tir | cm3 | 3456 |

| Poids du tir | g | 3145 |

| Vitesse de tir | mm/s | 821 |

| Diamètre de la vis | mm | 100 |

| Pression d'injection | MPa | 116 |

| Rapport L:D de vis | -- | 17.6 |

| UNITÉ DE SERRAGE | ||

| Force de serrage | kN | 5500 |

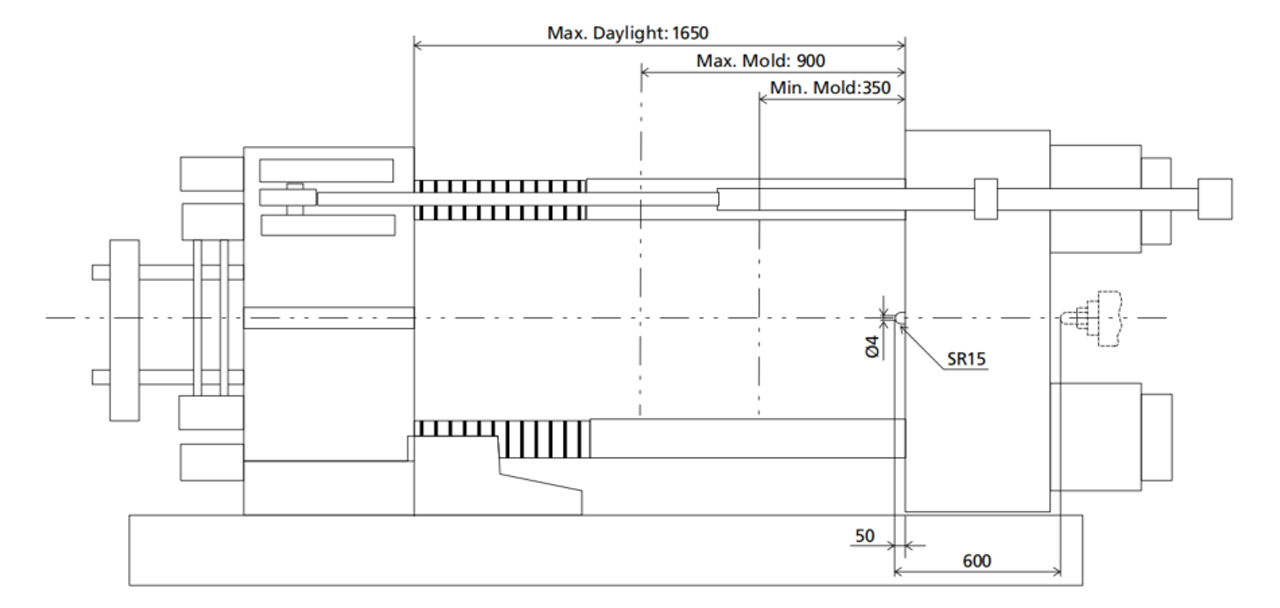

| Coup d'ouverture | mm | 1300 |

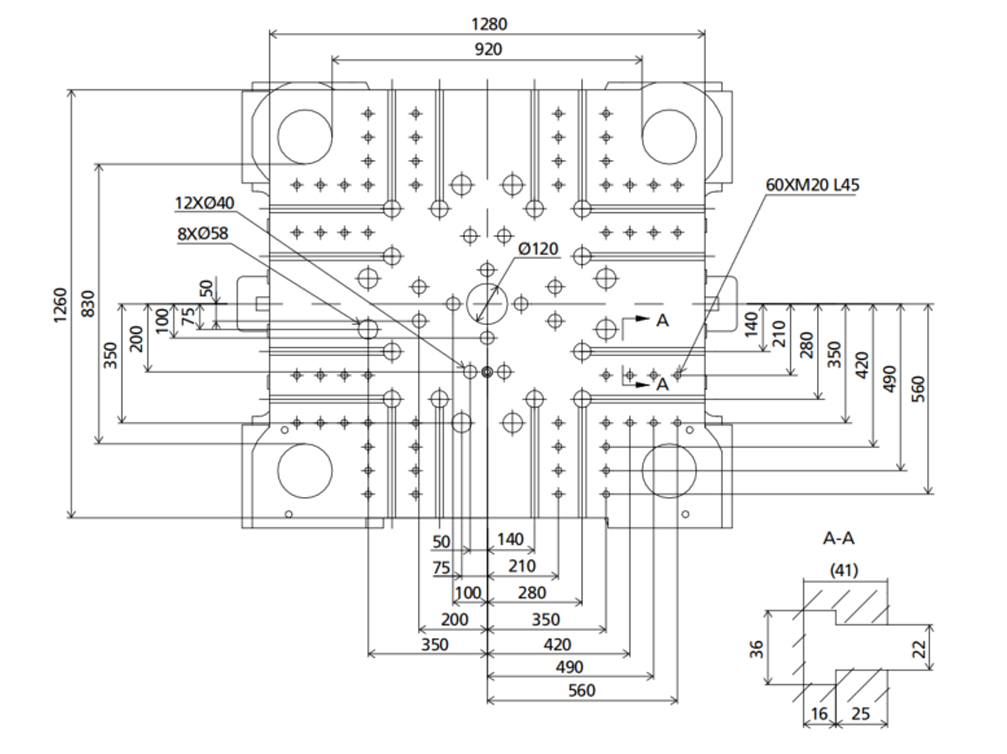

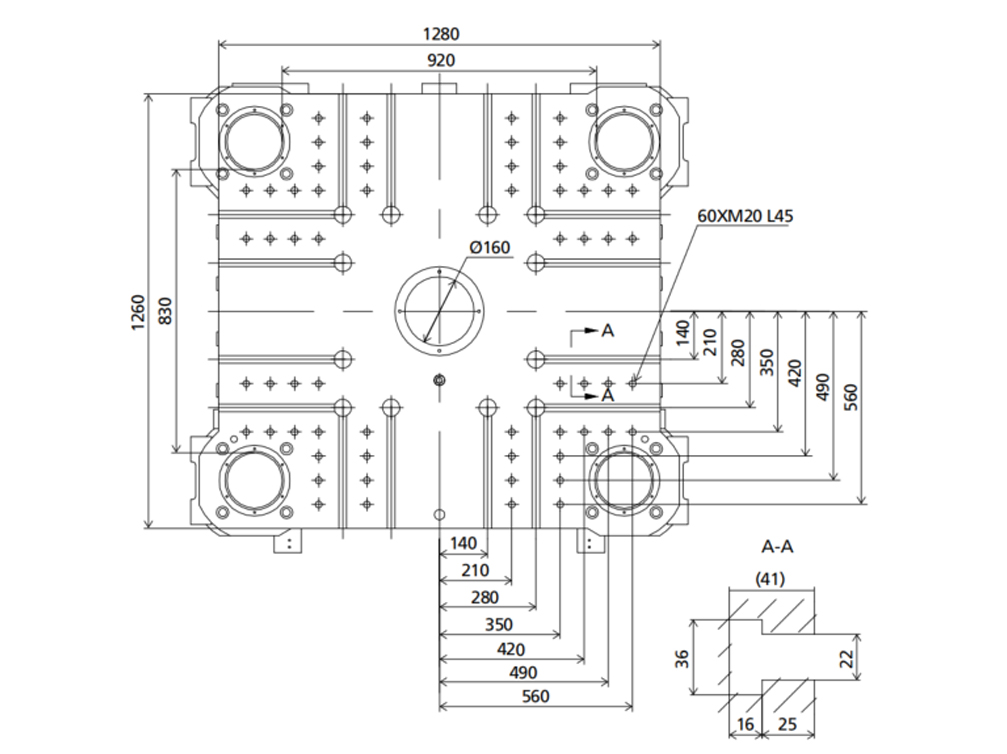

| Espace entre les barres de liaison | mm x mm | 920 x 830 |

| Épaisseur du moule(min) | mm | 350 |

| Épaisseur du moule(max) | mm | 900 |

| Course d'éjection hydraulique | mm | 250 |

| Force d'éjection hydraulique | kN | 110 |

| UNITÉ DE PUISSANCE | ||

| Moteur de pompe | kW | 65 |

| Capacité de chauffage | kW | 48 |

| GÉNÉRAL | ||

| Capacité du réservoir d'huile | L | 600 |

Clamping Unit

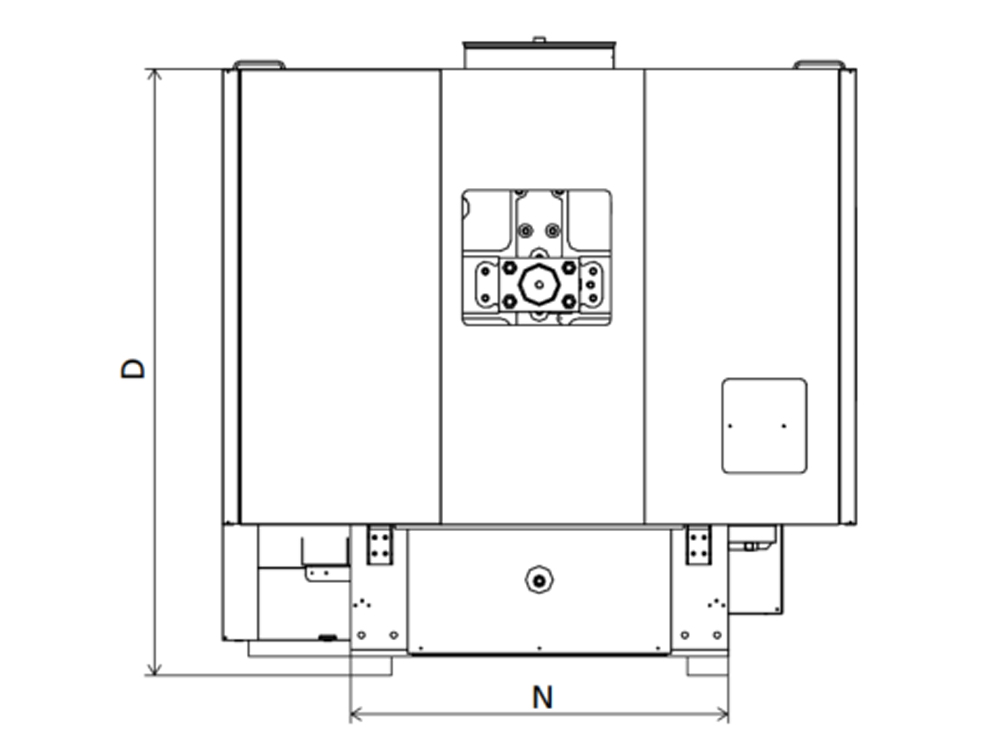

Platen Dimensions

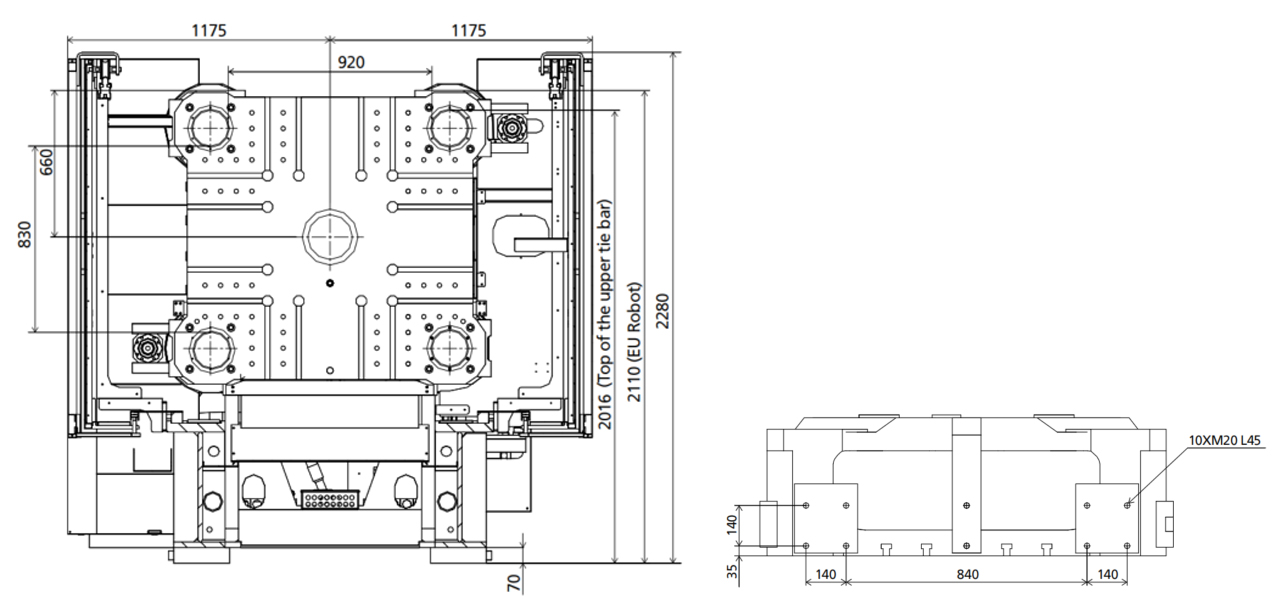

Robot

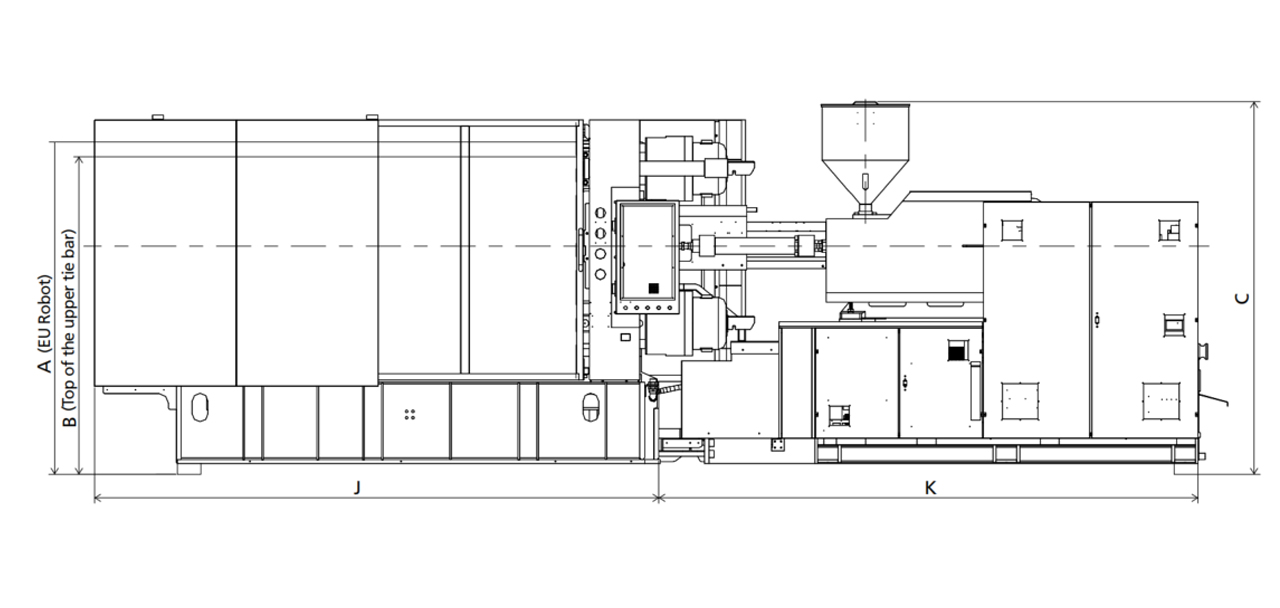

Front View

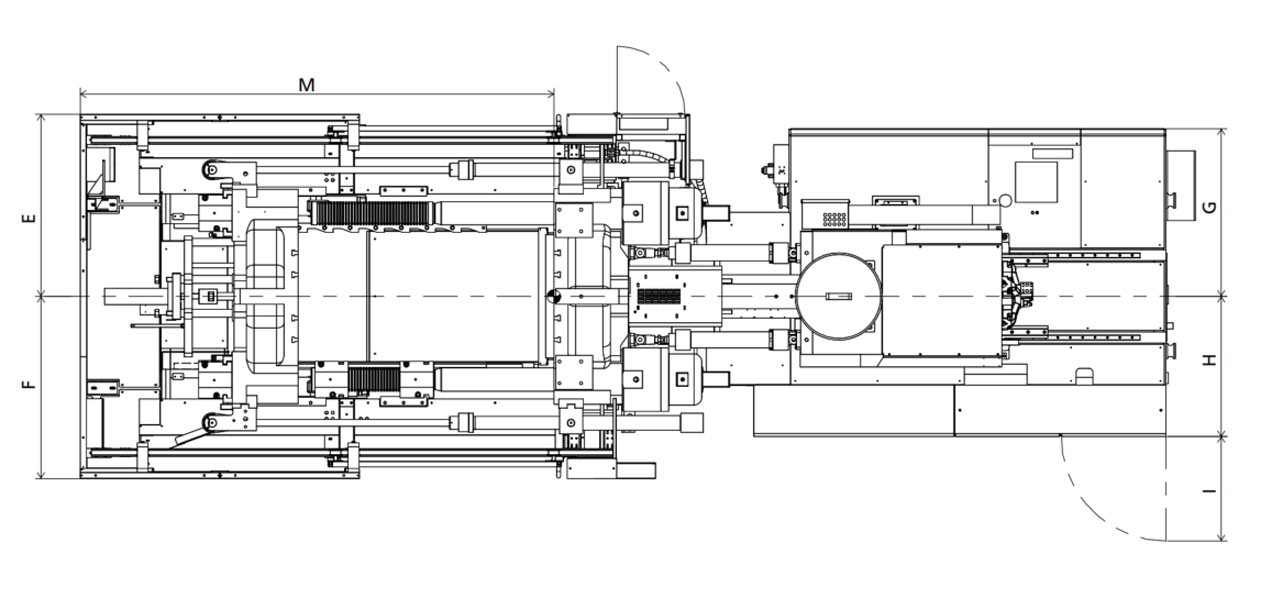

Top View

Side View

| # | Value |

|---|---|

| A | 2110 mm |

| B | 2016 mm |

| C | 2671 mm |

| D | 2250 mm |

| E | 1175 mm |

| F | 1175 |

| G | 1177 mm |

| H | 943 mm |

| I | 675 mm |

| J | 3581 mm |

| K | 4019 mm |

| M | 3056 mm |

| N | 1400 |

For 20/33L Pails IML Prodcution, Which Injection Molding Machine Would Be the Best One for This IML Project?

For the IML production of 20/33L pails, HaiDa machinery, which was founded in 1992, has a special high precision injection molding machine HD700U specialized for the IML production of 20/33L IML pails. With a clamping force of 700T and enlarged opening stroke up to 1060mm, which enable it to IML produce a deeper pails.

As a mate to Haida HD700U, the largest IML Robot among the SW8 Series of SWITEK Automation SW850 provide a perfect side entry IML solutions for the IML production of 20/33L pails. The combination of Haida HD700U + SWITEK SW850 IML Robot will provide the IML pails producer a price smart pails IML Solutions.

Actualités sur l'automatisation de l'injection à chaud

E-mail: sales@switek.biz

Contacter le blogueur

sales06@switek.biz

+86 186 5927 5869

DongGuan, GuangDong, China