sales06@switek.biz

+86 186 5927 5869

sales06@switek.biz

+86 186 5927 5869

| Description | Unité | Valeur |

|---|---|---|

| UNITÉ D'INJECTION | ||

| Volume de tir | cm3 | 1423 |

| Poids du tir | g | 1295 |

| Vitesse de tir | mm/s | 585 |

| Diamètre de la vis | mm | 75 |

| Pression d'injection | MPa | 137 |

| Rapport L:D de vis | -- | 18.7 |

| UNITÉ DE SERRAGE | ||

| Force de serrage | kN | 6500 |

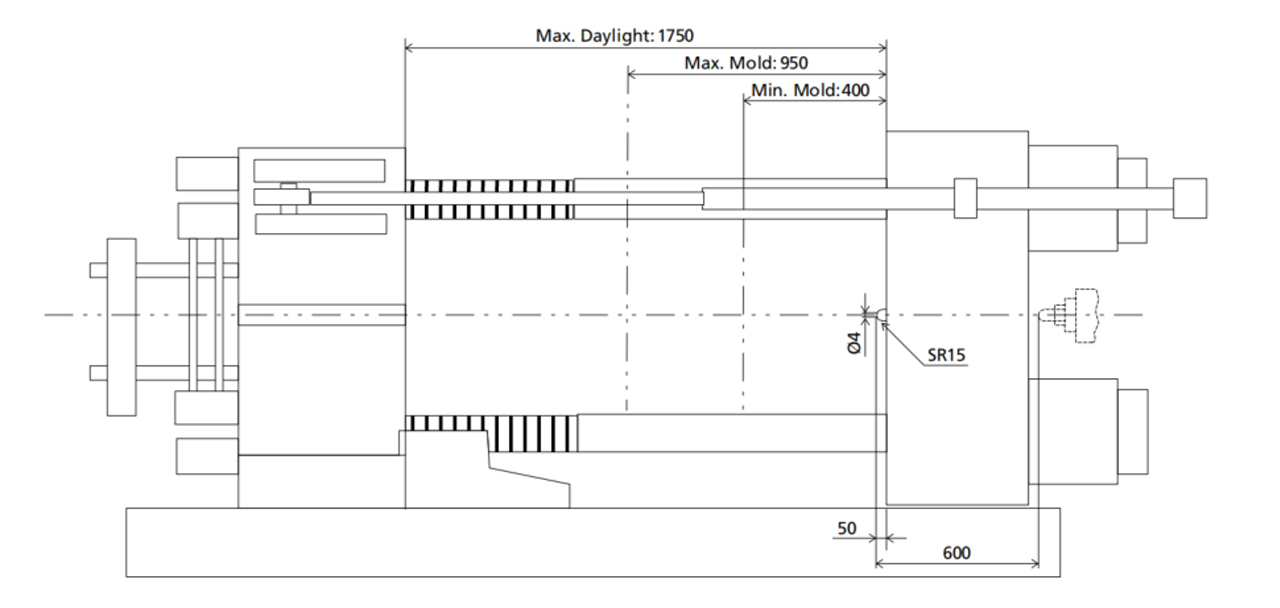

| Coup d'ouverture | mm | 1350 |

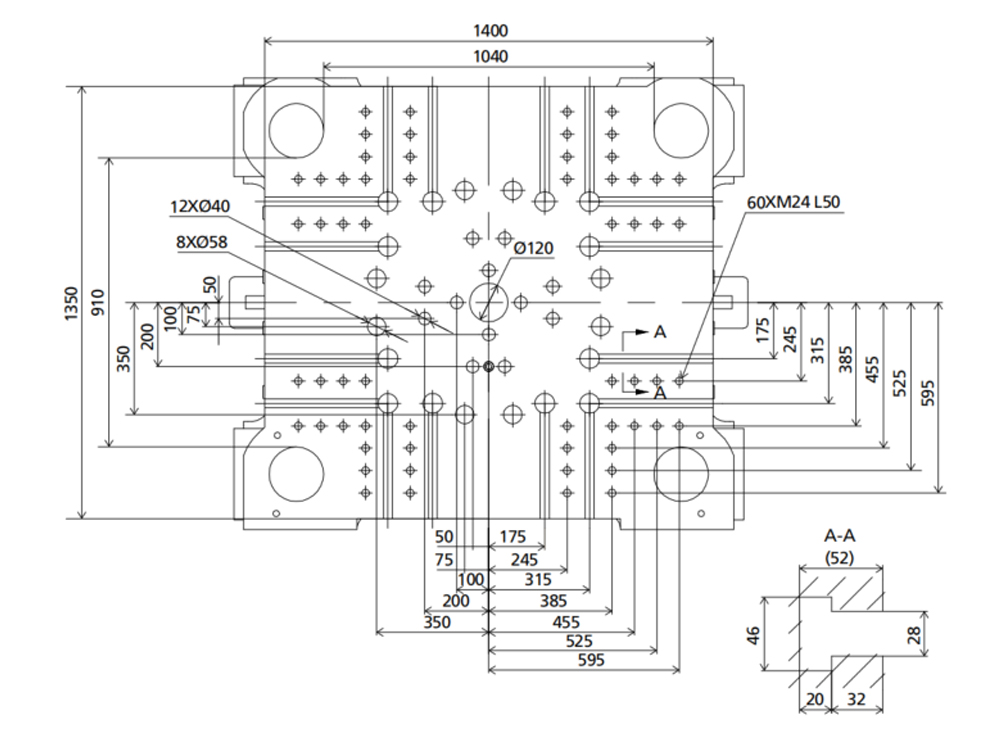

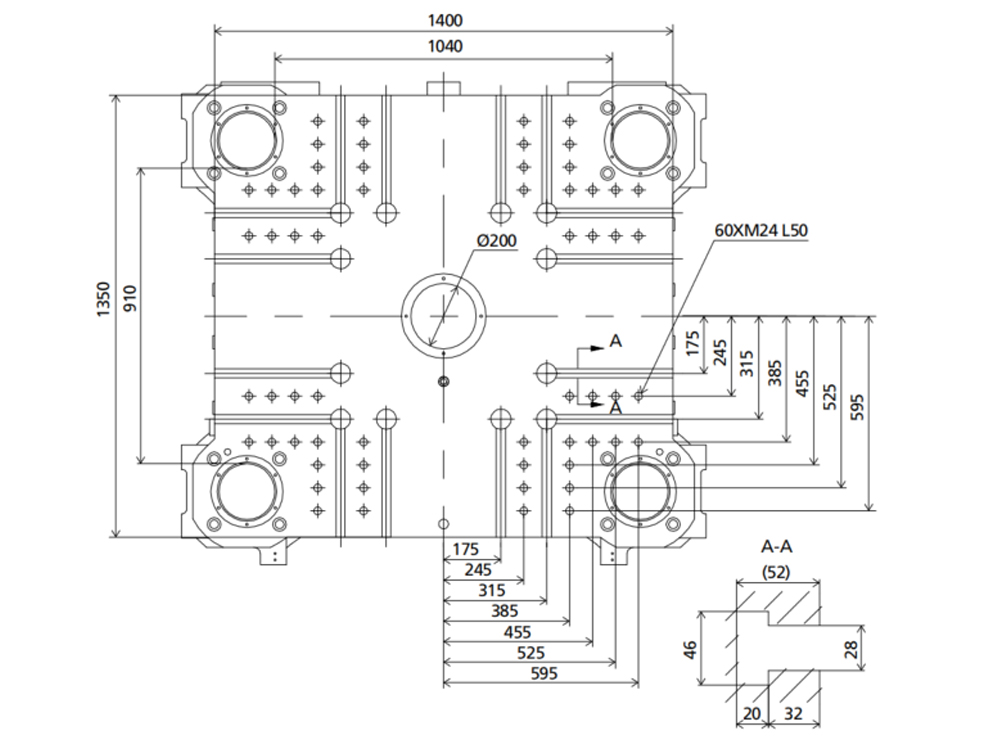

| Espace entre les barres de liaison | mm x mm | 1040 x 910 |

| Épaisseur du moule(min) | mm | 400 |

| Épaisseur du moule(max) | mm | 950 |

| Course d'éjection hydraulique | mm | 250 |

| Force d'éjection hydraulique | kN | 110 |

| UNITÉ DE PUISSANCE | ||

| Moteur de pompe | kW | 55 |

| Capacité de chauffage | kW | 33 |

| GÉNÉRAL | ||

| Capacité du réservoir d'huile | L | 450 |

Clamping Unit

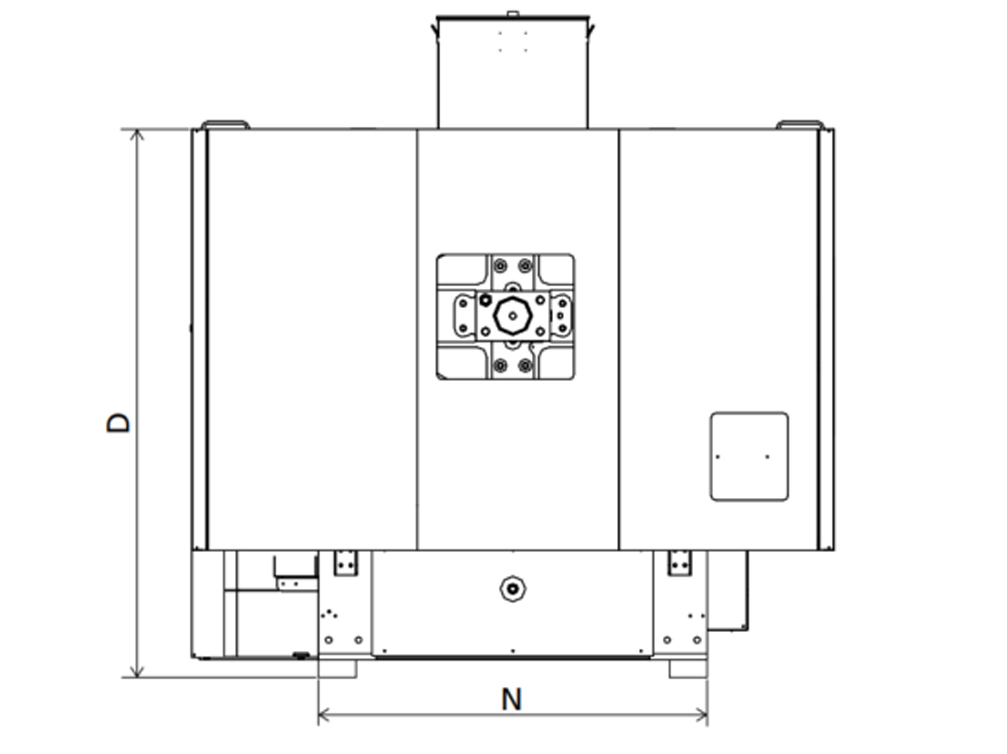

Platen Dimensions

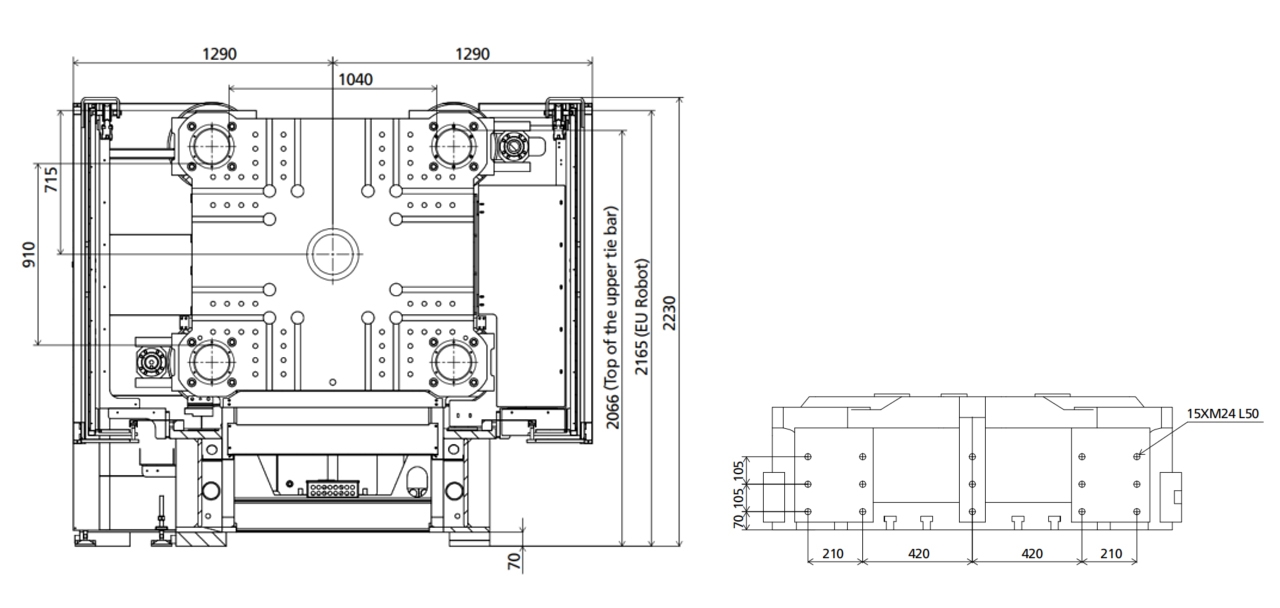

Robot

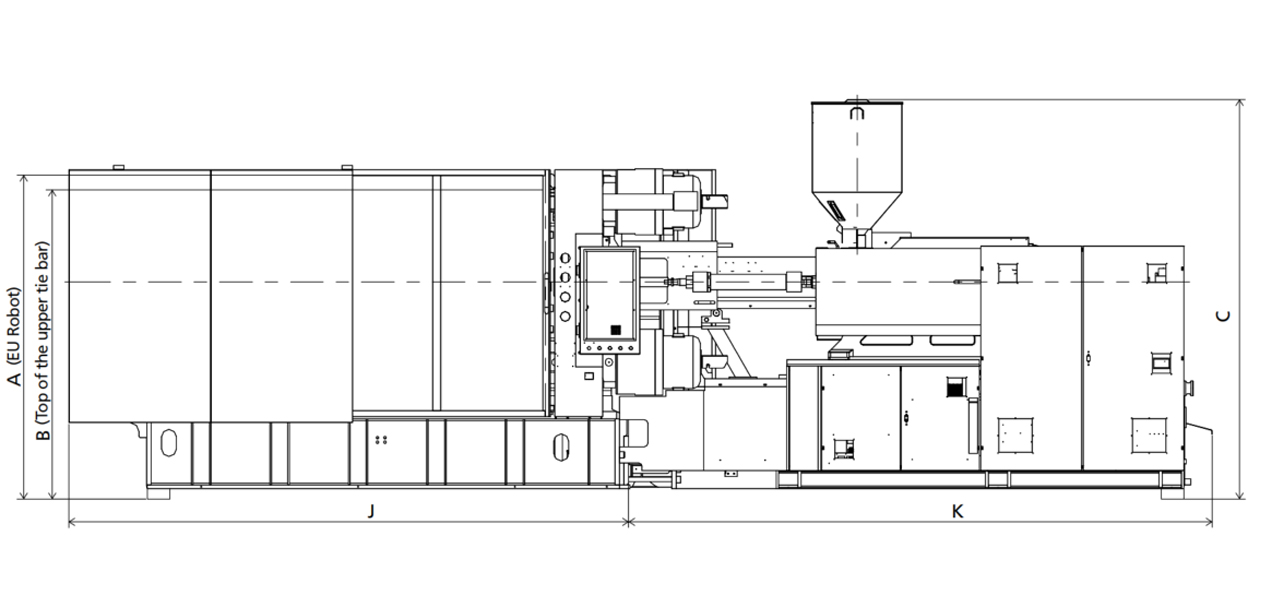

Front View

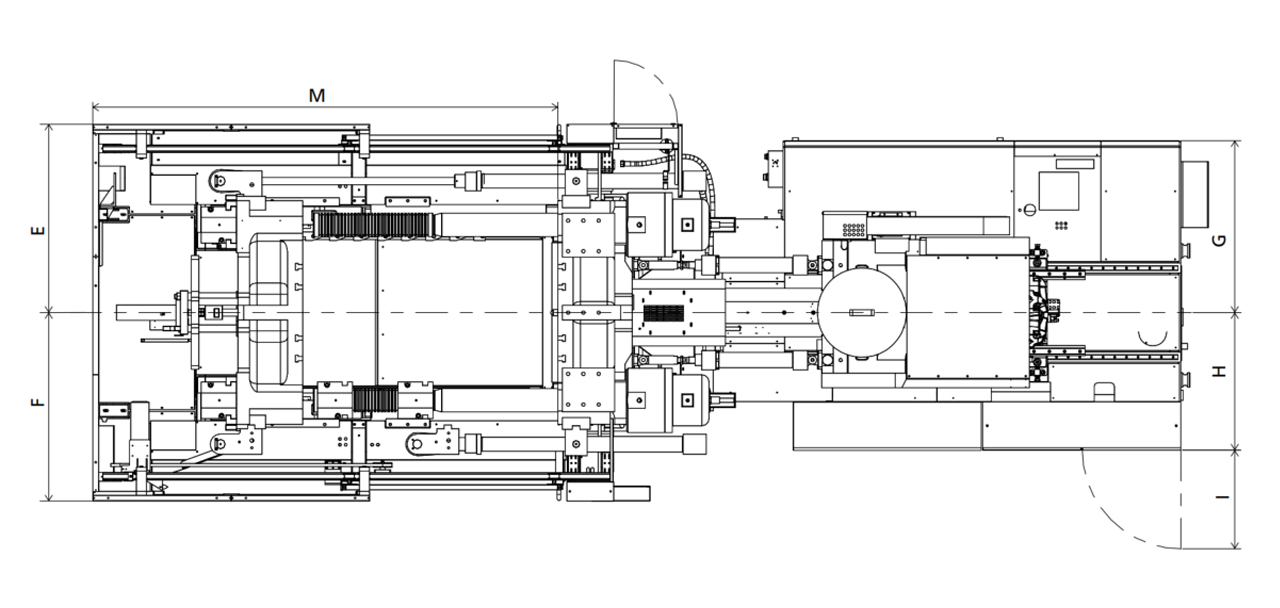

Top View

Side View

| # | Value |

|---|---|

| A | 2165 mm |

| B | 2066 mm |

| C | 2327 mm |

| D | 2200 mm |

| E | 1290 mm |

| F | 1290 |

| G | 1082 mm |

| H | 903 mm |

| I | 675 mm |

| J | 3746 mm |

| K | 3707 mm |

| M | 3191 mm |

| N | 1560 |

What Would be The Expectable Cycle Time In Production of 120ml Temper Evidence Cups With All Machineries Made In China?

With the advancement of technology, the injection machineries and automation solutions made in China are doing a much better job in thin-wall IML containers production. As for the production 120ml temper evidence cups for Yogurts, the best cycle time in a trial IML production of 6 cavities application with SWITEK SW8 Series IML robot and YIZUMI P380K3 high speed injection molding machine, the cycle time had been reduced to around 5.5s. Take the overall investment into consideration, it's an amazing bargin for the thin-wall IML containers producers in any world.

Actualités sur l'automatisation de l'injection à chaud

E-mail: sales@switek.biz

Contacter le blogueur

sales06@switek.biz

+86 186 5927 5869

DongGuan, GuangDong, China