sales06@switek.biz

+86 186 5927 5869

sales06@switek.biz

+86 186 5927 5869

| Description | Unit | Value |

|---|---|---|

| INJECTION UNIT | ||

| Shot volume | cm3 | 6769 |

| Shot weight | g | 6160 |

| Shot speed | mm/s | 1288 |

| Screw diameter | mm | 130 |

| Injection pressure | MPa | 116 |

| Screw L:D ratio | -- | 18.6 |

| CLAMPING UNIT | ||

| Clamping force | kN | 10800 |

| Opening Stroke | mm | 1900 |

| Space between tie bars | mm x mm | 1260 x 1100 |

| Mold thickness(min) | mm | 500 |

| Mold thickness(max) | mm | 1200 |

| Hydraulic ejection stroke | mm | 350 |

| Hydraulic ejection force | kN | 230 |

| POWER UNIT | ||

| Pump motor | kW | 112 |

| Heating capacity | kW | 83 |

| GENERAL | ||

| Oil tank capacity | L | 960 |

Clamping Unit

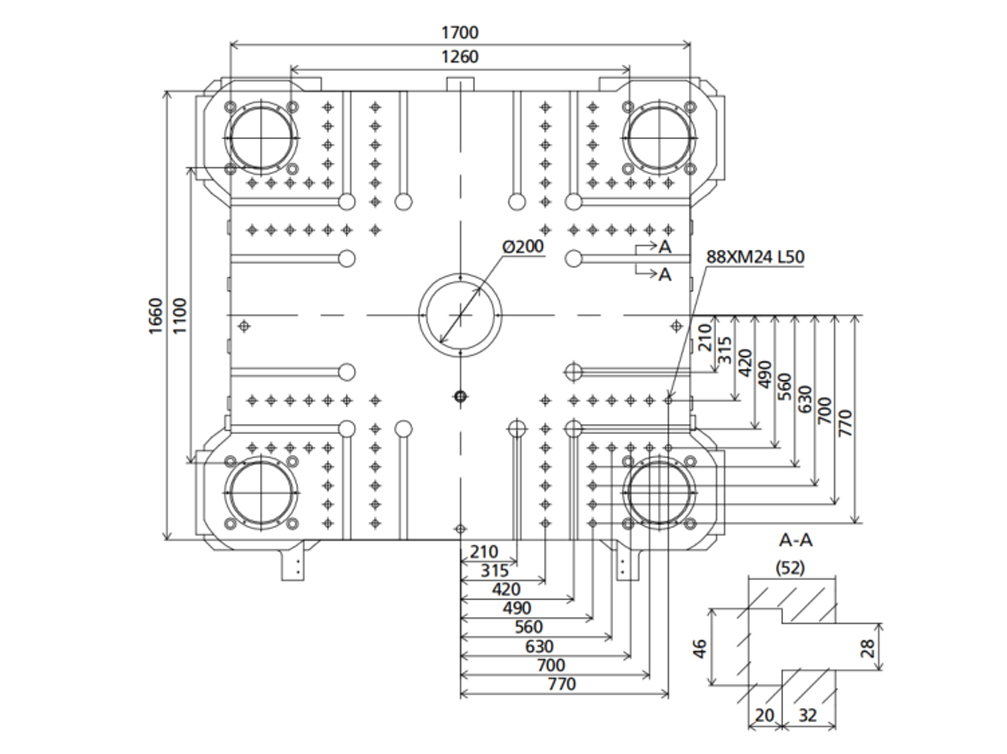

Platen Dimensions

Robot

Front View

Top View

Side View

| # | Value |

|---|---|

| A | 2470 mm |

| B | 2351 mm |

| C | 2850 mm |

| D | 2250 mm |

| E | 1676 mm |

| F | 1625 mm |

| G | 1228 mm |

| H | 1102 mm |

| I | 544 mm |

| J | 4699 mm |

| K | 4689 mm |

| M | 4014 mm |

| N | 1840 |

What's the advantage of a double arms robot top entry IML system for lids?

IML lids is now a business of billions of US dollar around the world especially as the package of dairy products. But as an easiest IML products to produce, IML lids is one of the most price sensitive products in the market. A smaller budget in facility investment and easier operating will no doubt help the IML lids producer to reduce their production and will be able to react faster to the market change.

For IML lids for small and medium size containers to be produced in injection molding machine around 350T, the cost of a double arms top entry IML system would be about one 2/3 against a side entry IML robot with similiar productivity. And since the robot is to be installed to the top of the injection molding machine, it'll occupy less floor space and maximize the the floor occupation of your working place. And as a top entry IML system it'll provide more flexibility to have the parts either dropped to the operator side or the non-operator side.

Hot Injection Automation News

E-mail: sales@switek.biz

Contact Blogger

sales06@switek.biz

+86 186 5927 5869

DongGuan, GuangDong, China