sales06@switek.biz

+86 186 5927 5869

sales06@switek.biz

+86 186 5927 5869

| Description | Unit | Value |

|---|---|---|

| INJECTION UNIT | ||

| Shot volume | cm3 | 2100 |

| Shot weight | g | 1911 |

| Shot speed | mm/s | 567 |

| Screw diameter | mm | 85 |

| Injection pressure | MPa | 141 |

| Screw L:D ratio | -- | 18.9 |

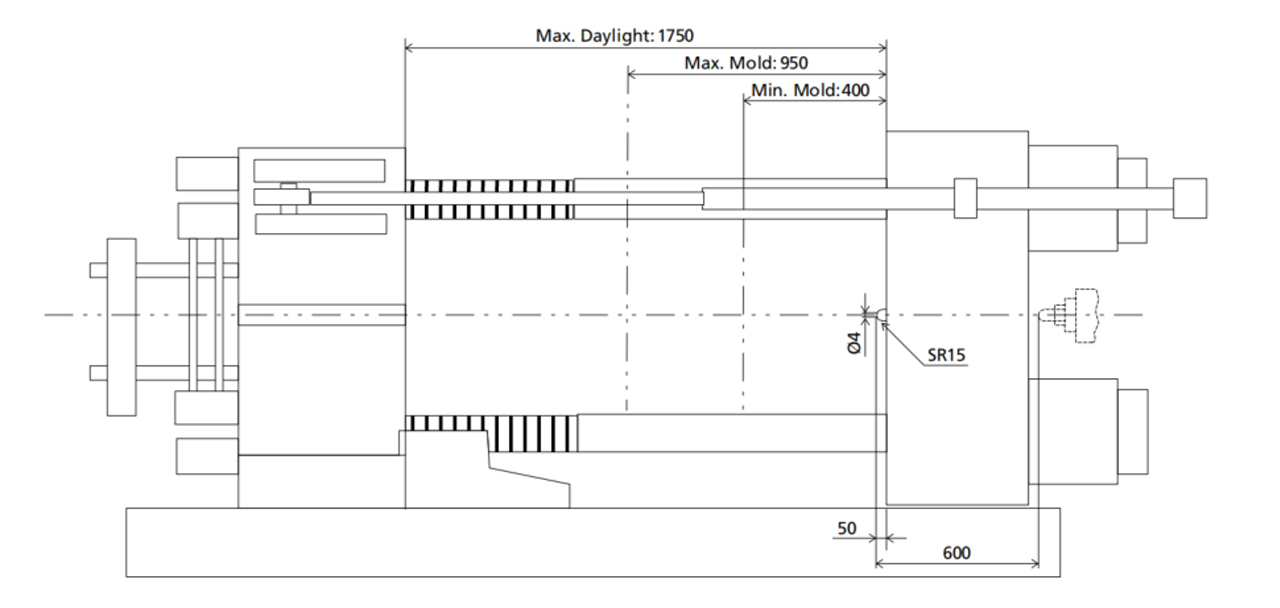

| CLAMPING UNIT | ||

| Clamping force | kN | 6500 |

| Opening Stroke | mm | 1350 |

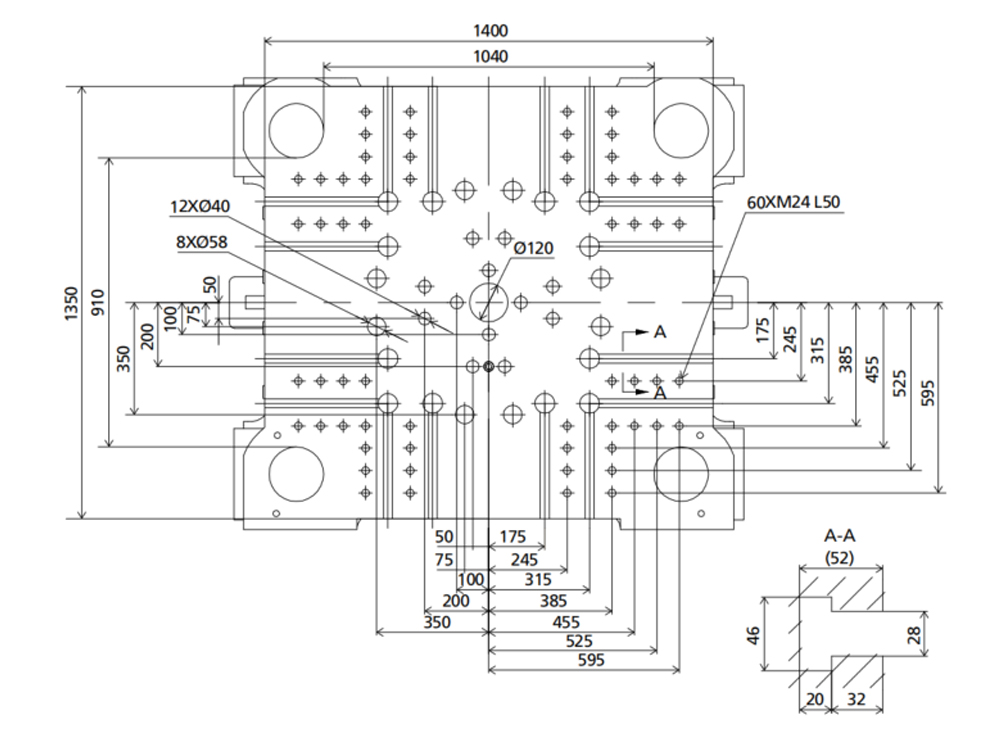

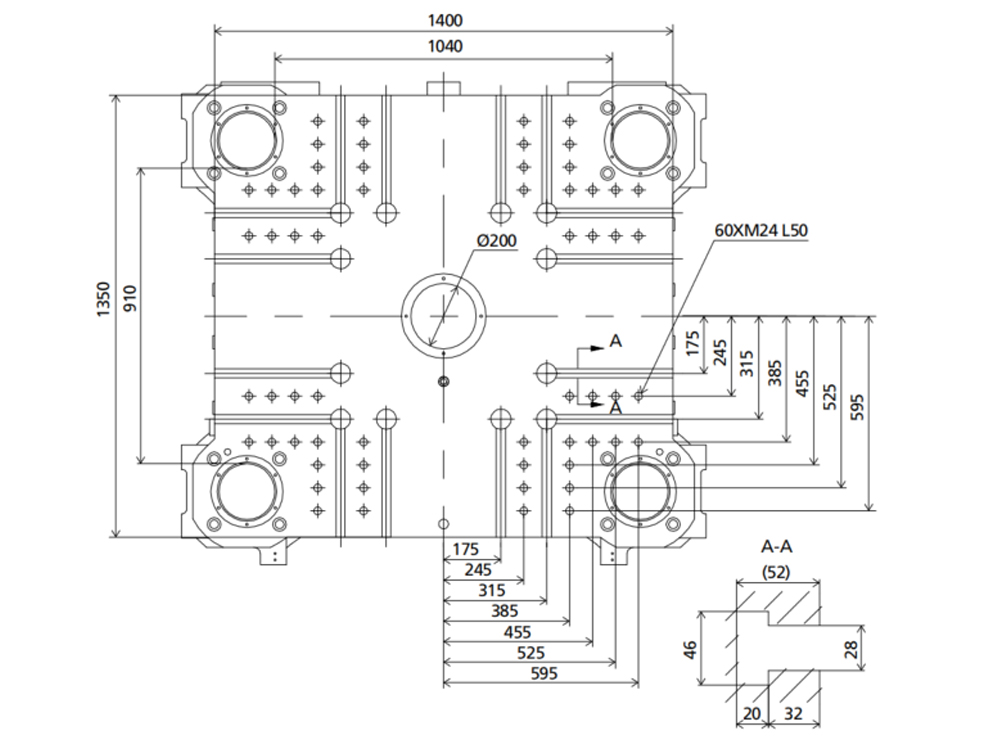

| Space between tie bars | mm x mm | 1040 x 910 |

| Mold thickness(min) | mm | 400 |

| Mold thickness(max) | mm | 950 |

| Hydraulic ejection stroke | mm | 250 |

| Hydraulic ejection force | kN | 110 |

| POWER UNIT | ||

| Pump motor | kW | 55 |

| Heating capacity | kW | 39 |

| GENERAL | ||

| Oil tank capacity | L | 520 |

Clamping Unit

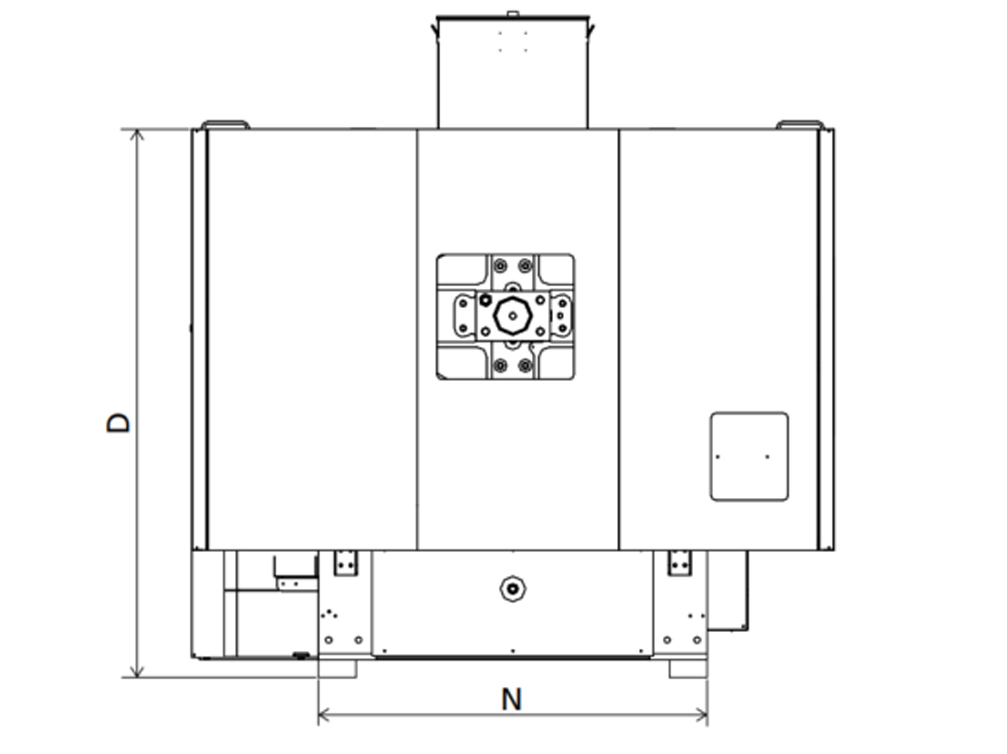

Platen Dimensions

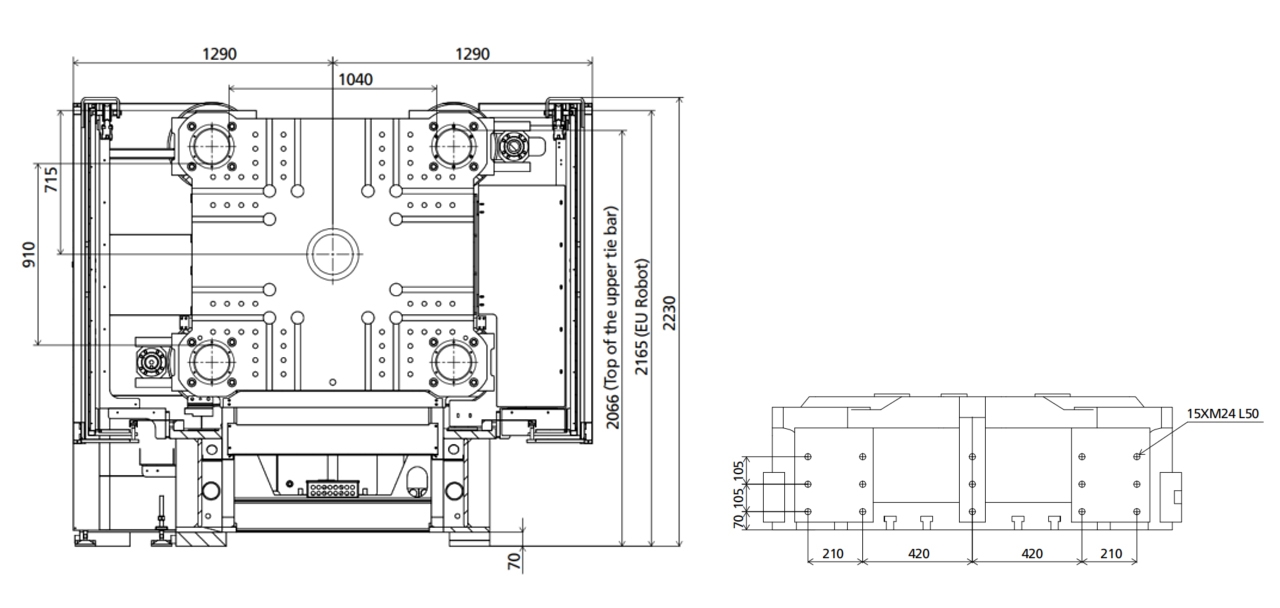

Robot

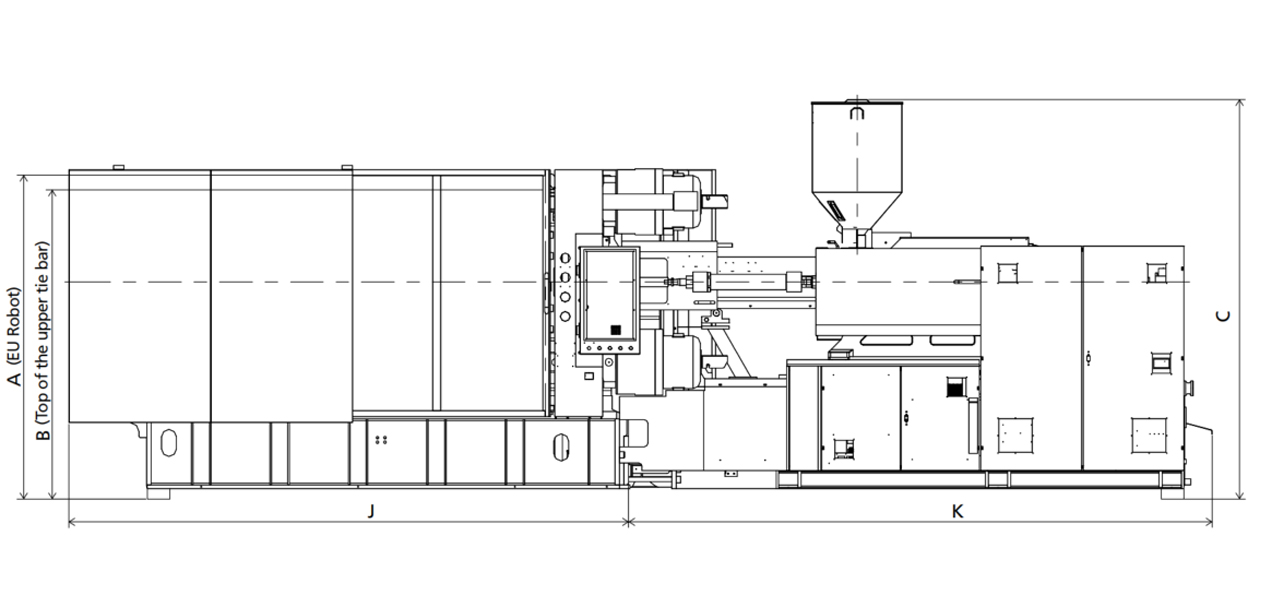

Front View

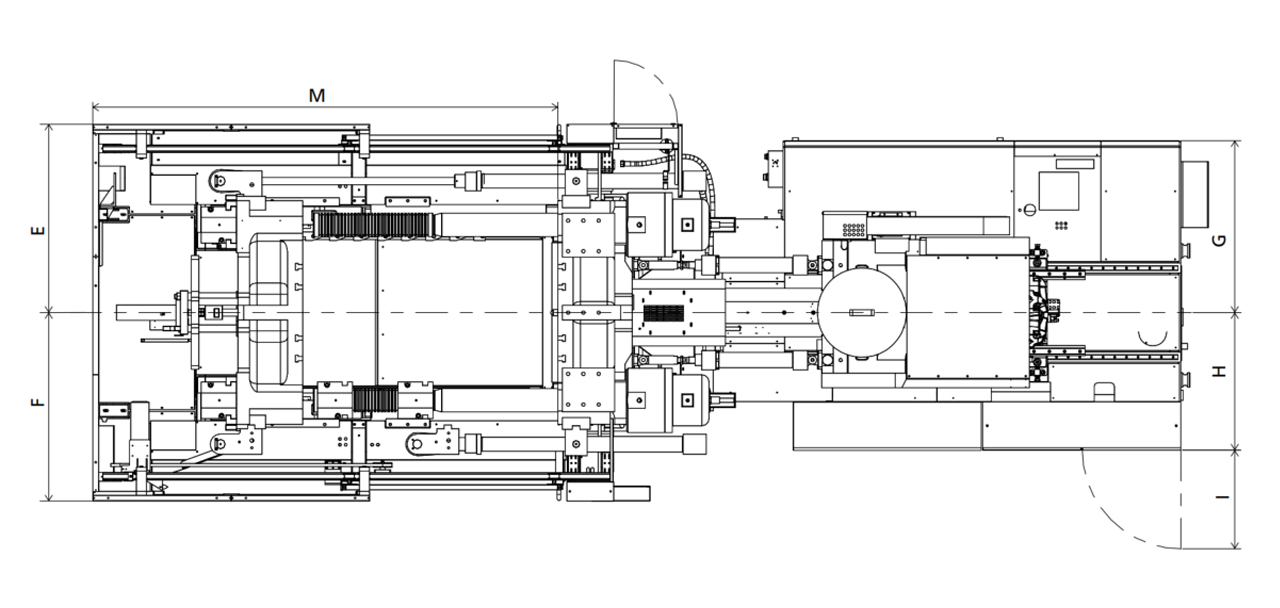

Top View

Side View

| # | Value |

|---|---|

| A | 2165 mm |

| B | 2066 mm |

| C | 2366 mm |

| D | 2200 mm |

| E | 1290 mm |

| F | 1290 |

| G | 1082 mm |

| H | 903 mm |

| I | 675 mm |

| J | 3746 mm |

| K | 3722 mm |

| M | 3191 mm |

| N | 1560 |

Welltec machinery in house testing turn-key 8+8 petri dish injection+picking+stacking solution in their new all electric injection molding machine 360HD with side entry robot.

Petri dish is one of the medical parts which requested in big quantity, one sets of the petri dish include one plate + one cover. A stack mold solution for the petri dish will maximize the productivity of the injection molding machine. It's a price smart solutions for petri dish production. The side entry robot will pick the cover and bottom plate from each side of the mold and have them stacked as one set with the help of the EOAT to be stacked again for packing. The precision of and the speed of the side entry robot are in high demand to make a success system.

Another solutions for petri dish production is an 8 cavities mould with 4 cover + 4 botton dish in the same mould with a high speed 3 axis servo injectio robot to pick them out and then to stack them as one set with the help of the EOAT. SWITEK petri dish top entry robot picking and packing system can well finish the the picking, assemble, stacking and packing automatically. It's an easier solutions for petri dish production and packing.

Turn-key IML Solutions

Turn-key Pipe Fittings Injection Automation Solutions

Turn-key Cutlery Packing Automation Solutions

High Performance Injection Robot

Contact Blogger

sales06@switek.biz

+86 186 5927 5869

DongGuan, GuangDong, China