sales06@switek.biz

+86 186 5927 5869

sales06@switek.biz

+86 186 5927 5869

| Description | Unit | Value |

|---|---|---|

| INJECTION UNIT | ||

| Shot volume | cm3 | 2354 |

| Shot weight | g | 2142 |

| Shot speed | mm/s | 636 |

| Screw diameter | mm | 90 |

| Injection pressure | MPa | 126 |

| Screw L:D ratio | -- | 17.8 |

| CLAMPING UNIT | ||

| Clamping force | kN | 6500 |

| Opening Stroke | mm | 1350 |

| Space between tie bars | mm x mm | 1040 x 910 |

| Mold thickness(min) | mm | 400 |

| Mold thickness(max) | mm | 950 |

| Hydraulic ejection stroke | mm | 250 |

| Hydraulic ejection force | kN | 110 |

| POWER UNIT | ||

| Pump motor | kW | 55 |

| Heating capacity | kW | 39 |

| GENERAL | ||

| Oil tank capacity | L | 520 |

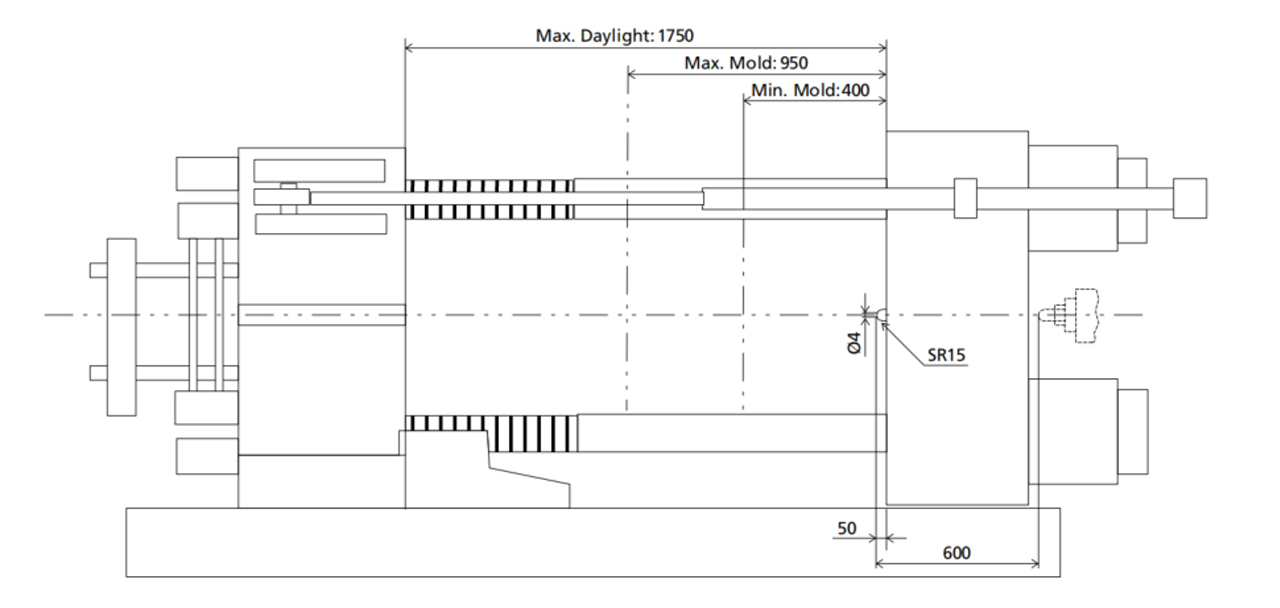

Clamping Unit

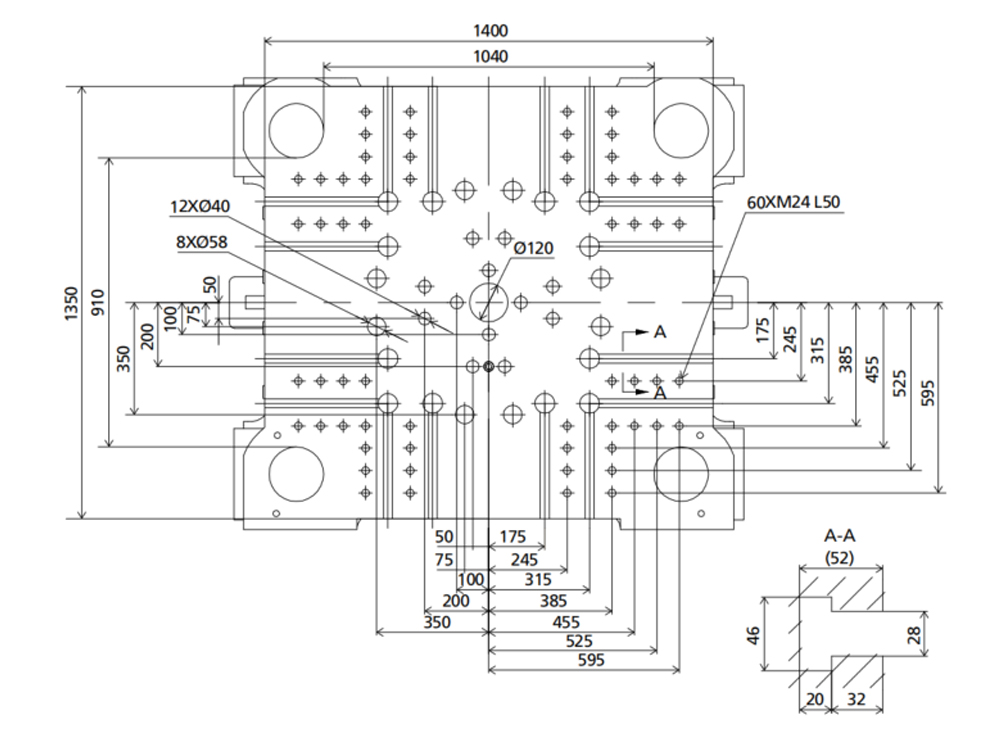

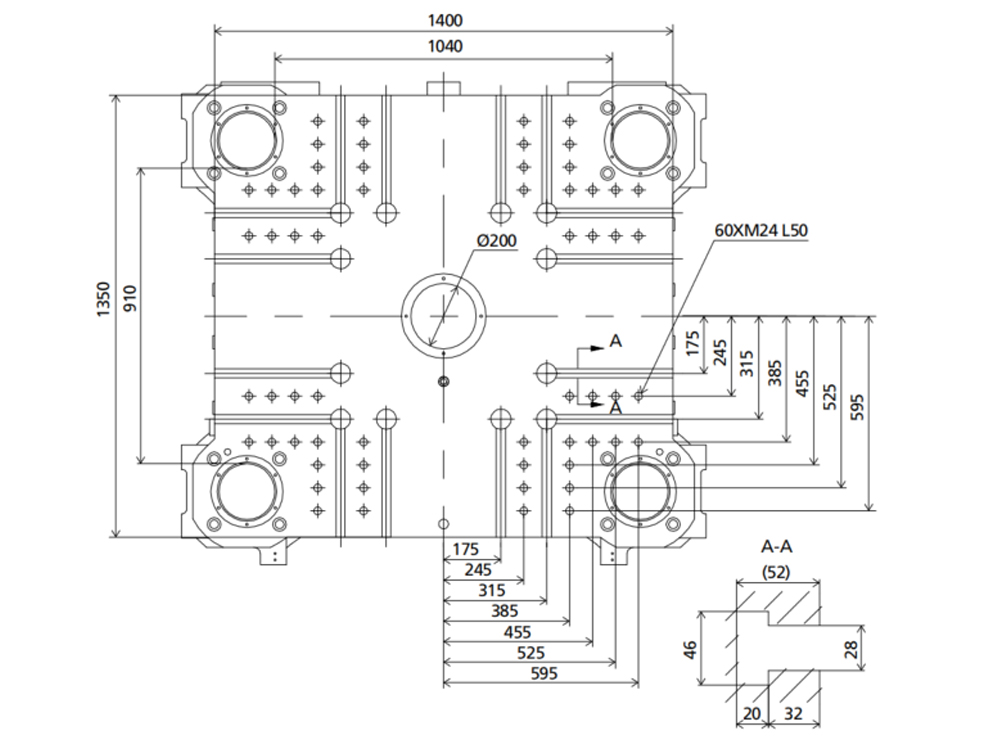

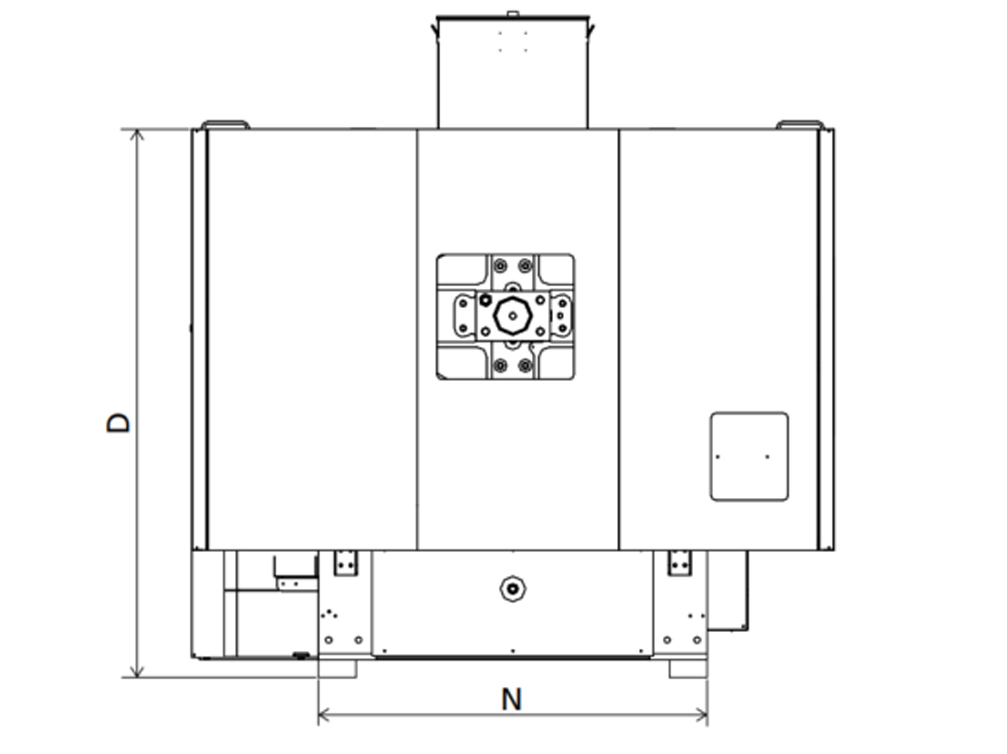

Platen Dimensions

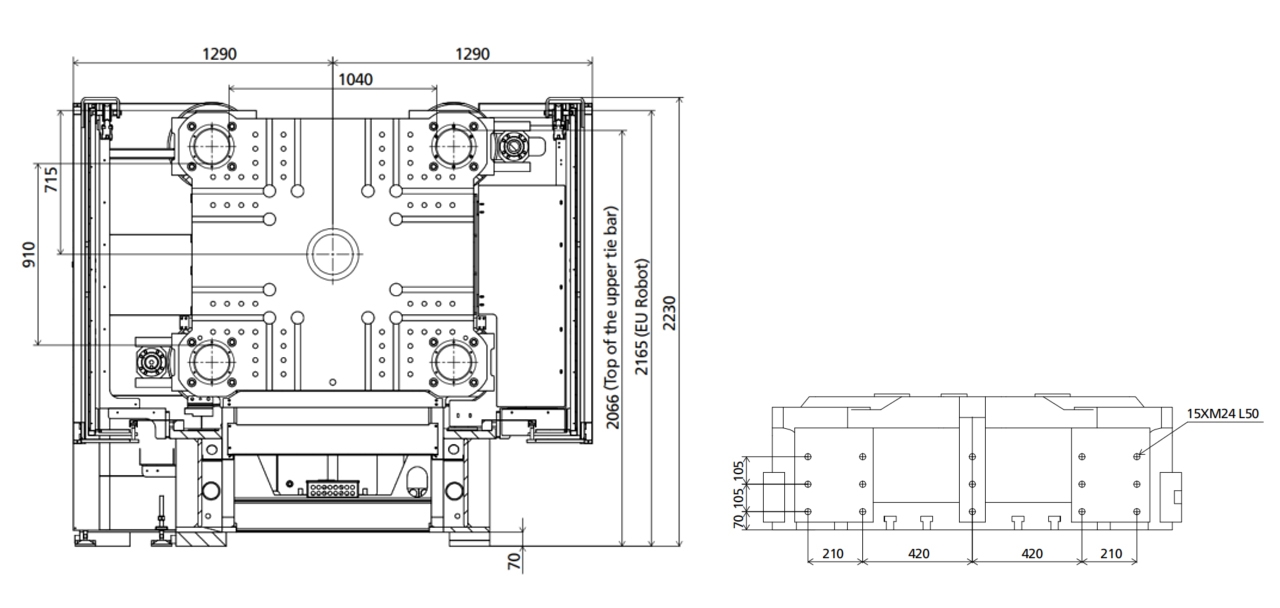

Robot

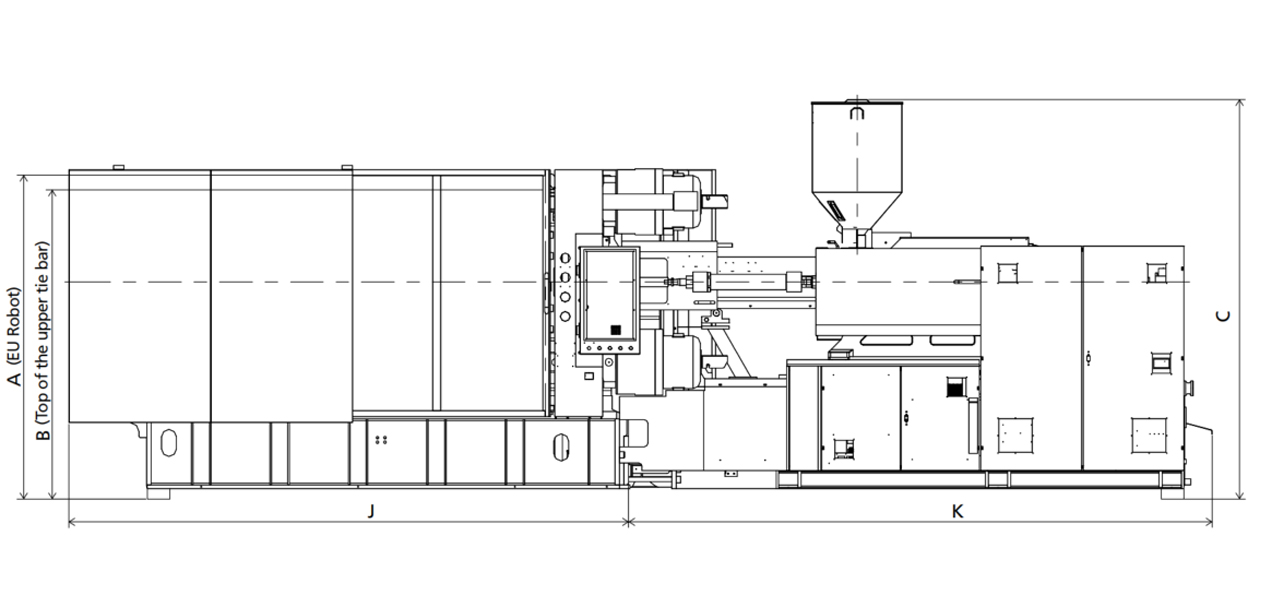

Front View

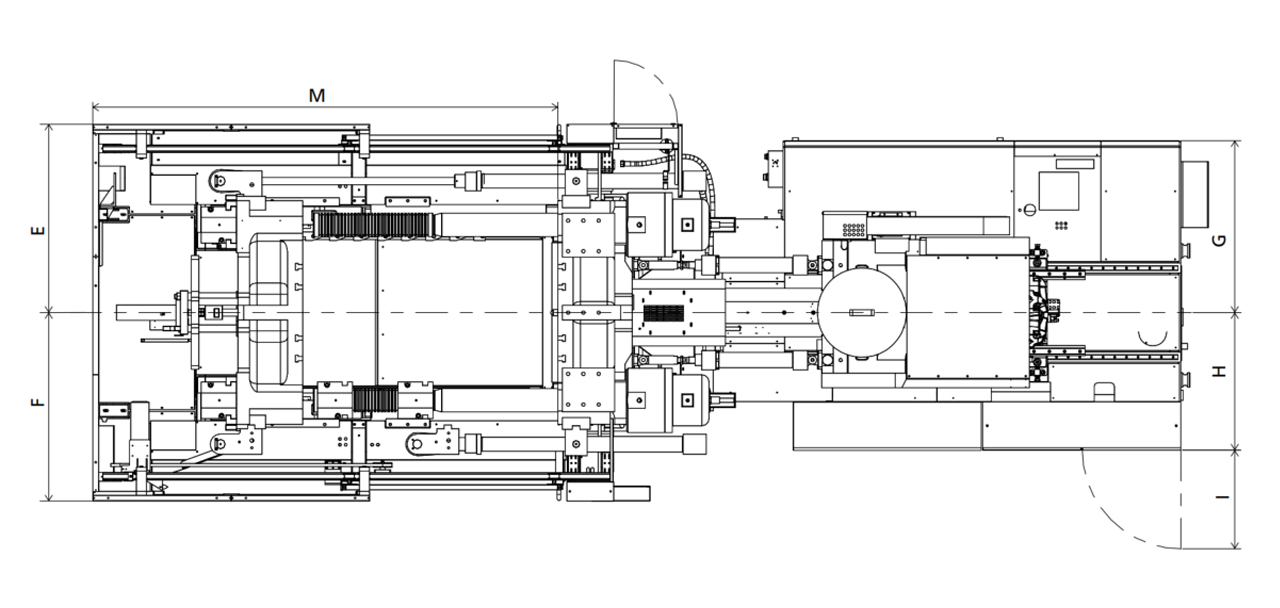

Top View

Side View

| # | Value |

|---|---|

| A | 2165 mm |

| B | 2066 mm |

| C | 2366 mm |

| D | 2200 mm |

| E | 1290 mm |

| F | 1290 |

| G | 1082 mm |

| H | 903 mm |

| I | 675 mm |

| J | 3746 mm |

| K | 3722 mm |

| M | 3191 mm |

| N | 1560 |

What's Would be the Most Economic Way to Produce An IML Bucket With Handle?

As one of the most popular food package in the market, an IML pail with handle is in demand of huge quantity but the assembly of the handle make it a labour entensive products. Is there any solutions that will make the production of an IML bucket with handle automatically? The answer would definitely yes.

One of the most economic way would be to have the pails and handle integrated into one single mold, it could be 2 + 2 or 4 + 4 design which the IML robot will pick the buckets and have the handles assembled automatically. With this solution, the IML buckets producer will only need one set of IML system to have the buckets and handle produced and assembled immediately.

> It sounds great right, but what would be the productivity of such a system? In Chinaplas 2024 SWITEK cooperated with YIZUMI onshowed a 2 + 2 IML solution of 1L pails at the cycle time of around 7.5s. Generally the performance of the injection molding machine, the mold and the IML robot are all very important to make it a perfect IML system with handle assembly.

Fore more questions about your IML projects, please feel free to contact Adams from SWITEK, your personal consultant of IML technology.

Hot Injection Automation News

E-mail: sales@switek.biz

Contact Blogger

sales06@switek.biz

+86 186 5927 5869

DongGuan, GuangDong, China