sales06@switek.biz

+86 186 5927 5869

sales06@switek.biz

+86 186 5927 5869

| Description | Unit | Value |

|---|---|---|

| INJECTION UNIT | ||

| Shot volume | cm3 | 862 |

| Shot weight | g | 0 |

| Shot speed | mm/s | 160 |

| Screw diameter | mm | 65 |

| Injection pressure | MPa | 164 |

| Screw L:D ratio | -- | 25 |

| CLAMPING UNIT | ||

| Clamping force | kN | 3800 |

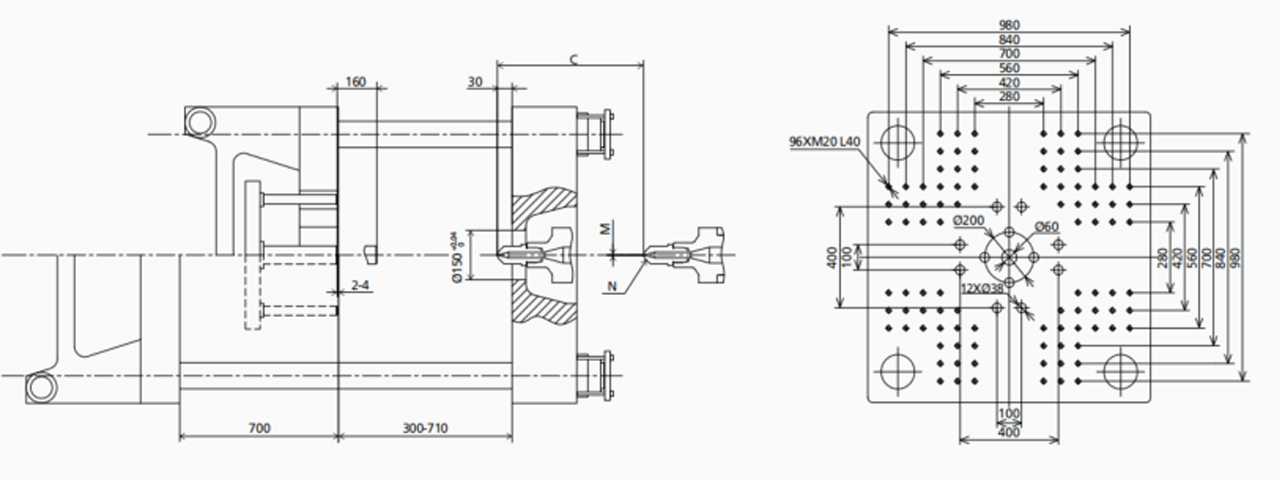

| Opening Stroke | mm | 700 |

| Space between tie bars | mm x mm | 770 x 770 |

| Mold thickness(min) | mm | 300 |

| Mold thickness(max) | mm | 710 |

| Hydraulic ejection stroke | mm | 160 |

| Hydraulic ejection force | kN | 69 |

| POWER UNIT | ||

| Pump motor | kW | 168 |

| Heating capacity | kW | 0 |

| GENERAL | ||

| Oil tank capacity | L | 135 |

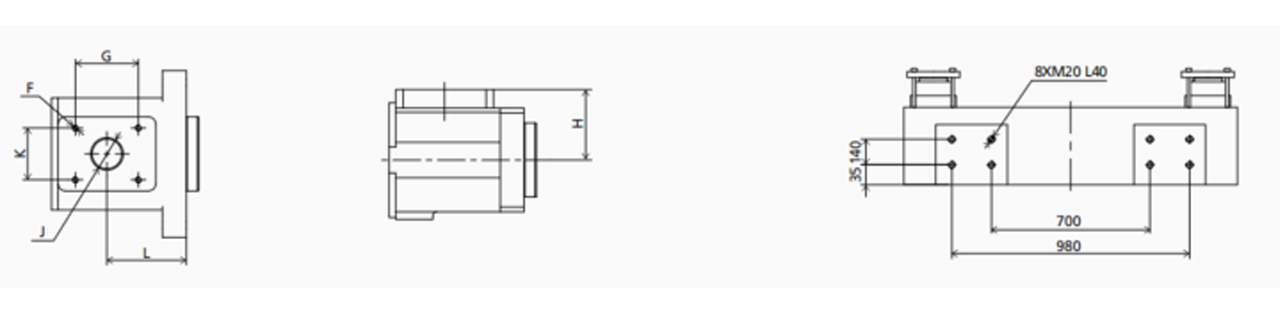

Robot Installation

Platen Dimension

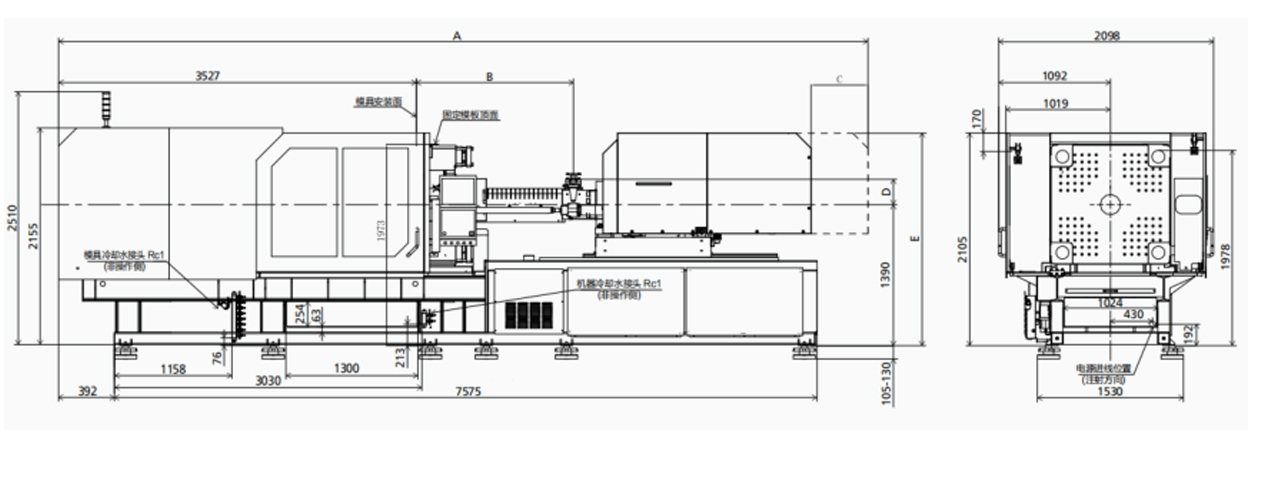

Machine Dimmension

| # | Value |

|---|---|

| A | 8044 mm |

| B | 1615 mm |

| C | 610 mm |

| D | 251 mm |

| E | 2095 mm |

| F | 4 x M10 L20 |

| G | 115 mm |

| H | 149 mm |

| J | φ80 mm |

| K | 115 mm |

| L | 184 mm |

| M | φ4 mm |

| N | SR10 |

Why is the high speed 3 axis servo injection robot SW7112DS one of the best buy high speed robot for thin-wall containers?

For thin-wall containers producers, since the thin-wall containers are low price products and is an easy to start business, it make the thin-wall containers business a highly competitive one. To get the investment back fast, you'll try to:

Not only as the picking robot of the thin-wall containers, SW7112DS is also one of the core robot in some packing system which request a fast picking and stacking of the parts. The automation solutions with a SW7112DS as the core picking robot include the Jerry Cups Packing System; Petri Dish Packing System etc. Anyway, SWITEK SW7112DS is one of the best choice for your fast picking and packing injection automation projects.

Turn-key IML Solutions

Turn-key Pipe Fittings Injection Automation Solutions

Turn-key Cutlery Packing Automation Solutions

High Performance Injection Robot

Contact Blogger

sales06@switek.biz

+86 186 5927 5869

DongGuan, GuangDong, China