| Description | Unit | Value |

|---|---|---|

| INJECTION UNIT | ||

| Shot volume | cm3 | 735 |

| Shot weight | g | 0 |

| Shot speed | mm/s | 160 |

| Screw diameter | mm | 60 |

| Injection pressure | MPa | 193 |

| Screw L:D ratio | -- | 25 |

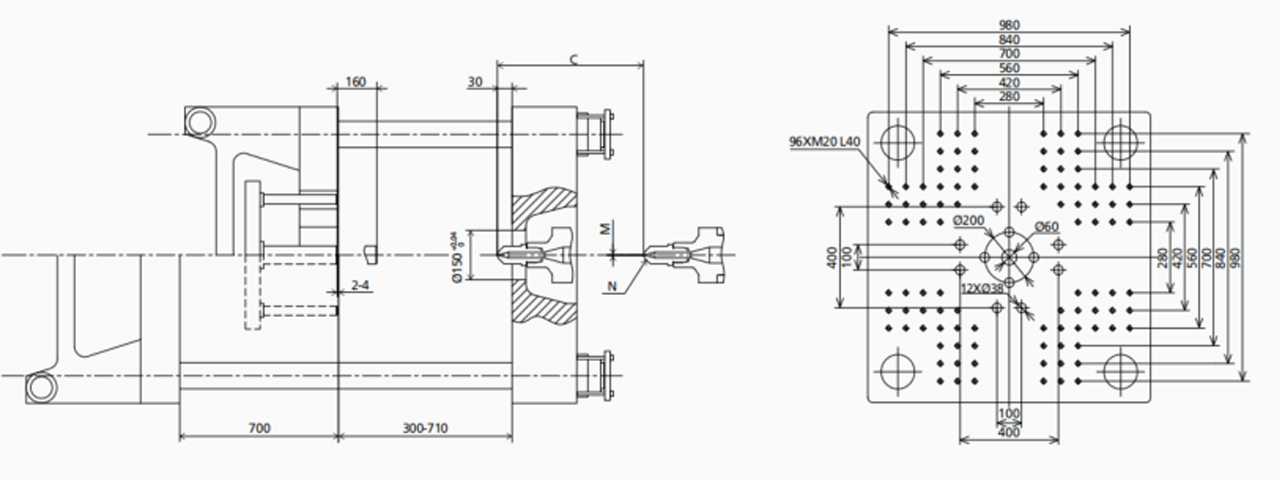

| CLAMPING UNIT | ||

| Clamping force | kN | 3800 |

| Opening Stroke | mm | 700 |

| Space between tie bars | mm x mm | 770 x 770 |

| Mold thickness(min) | mm | 300 |

| Mold thickness(max) | mm | 710 |

| Hydraulic ejection stroke | mm | 160 |

| Hydraulic ejection force | kN | 69 |

| POWER UNIT | ||

| Pump motor | kW | 168 |

| Heating capacity | kW | 0 |

| GENERAL | ||

| Oil tank capacity | L | 135 |

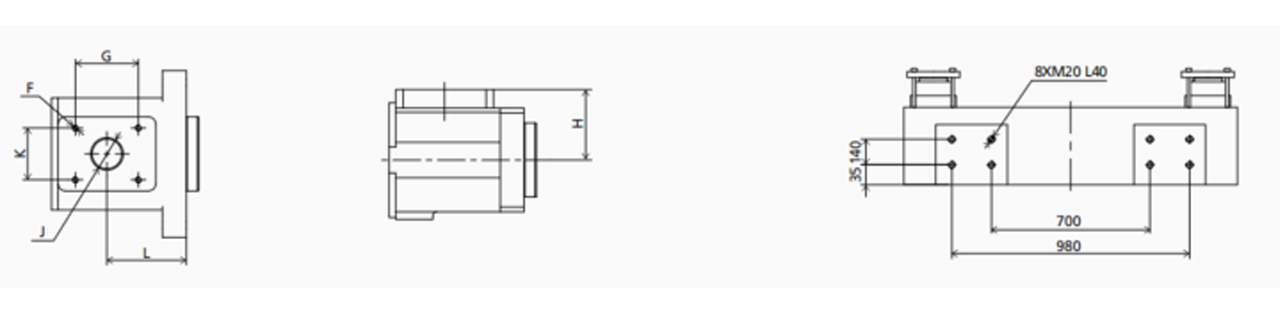

Robot Installation

Platen Dimension

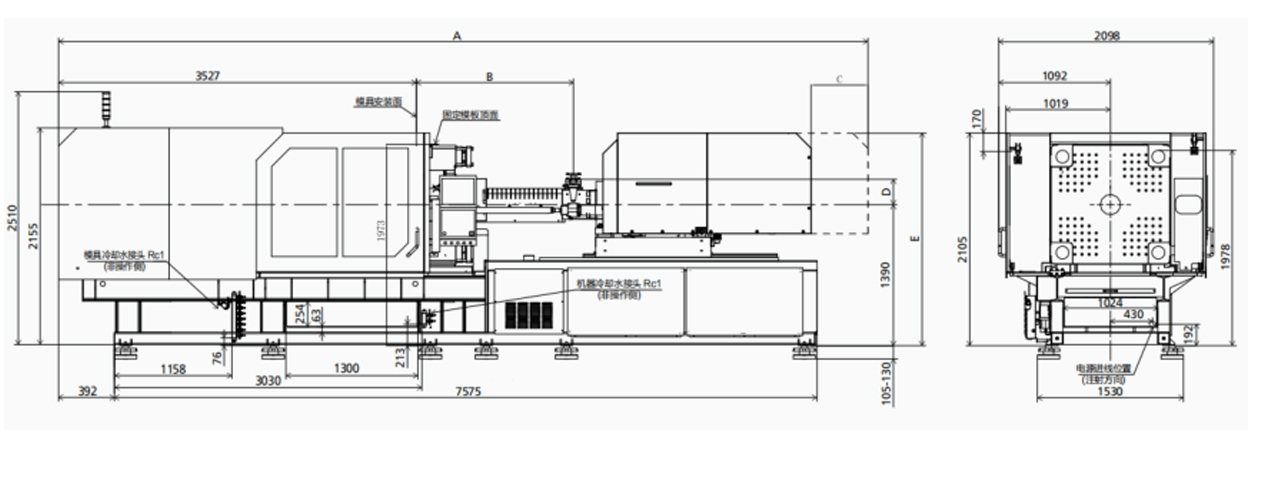

Machine Dimmension

| # | Value |

|---|---|

| A | 8044 mm |

| B | 1615 mm |

| C | 610 mm |

| D | 251 mm |

| E | 2095 mm |

| F | 4 x M10 L20 |

| G | 115 mm |

| H | 149 mm |

| J | φ80 mm |

| K | 115 mm |

| L | 184 mm |

| M | φ4 mm |

| N | SR10 |

Roboplas onshow IML Solutions of 4 cavities box 5 faces IML labeling with visual control and boxing.

5 Face IML labeling is a popular decorating of the butter box which is efficient in producing. The IML System Roboplas onshow is a turn-key IML solution which integrated the visual control and boxing of a 5 face IML labeling of the butter box for the highest productivity and free from biomatic pollution during production.

The counter part of this system is the side entry IML System designed by SWITEK Automation for the production of AMUL butter box in India. As the leading dairy products producer in India, there're more than 5 IML robots by SWITEK among the package supplier of Amul in production of the containers for Amul butter with a simplified system of which provide only IML labeling. Of course without visual control and boxing the cost of the SWITEK IML System would be much lower compared to the Roboplas solution. Which will make the starting of the IML project much easier for small and medium sized package producers.

Turn-key IML Solutions

Turn-key Pipe Fittings Injection Automation Solutions

Turn-key Cutlery Packing Automation Solutions

High Performance Injection Robot

ไอเอ็มแอล เทคโนโลยี เอ็กซ์เพรส

Hwamda Machinery New High Speed Injection Robot HMD 320M8 Started Up in a Pail Production Project

Haida представила на Руспласте новую гибридную термопластавтомат

Fakuma 2023 -- ENGEL on Show their All Electric Injection Molding Machine with Turn-key IML Solutions

Roboplas Onshow 4 Cavities Boxex 5 Faces IML Solution at Plastpol 2013

CHINAPLAS 2023 | Chinaplas High Speed Injection Molding Machine Manufacturer HMD will Unveil New High Speed All Electric Injection Molding Machine

ARGE Side Entry IML System for 1200cc Buckets In Production with BMBKW28 Injection Molding Machine

BOLE New EKH Series Injection Molding Machine Installed in Thailand for Car-parts Production

SWITEK new 2 cavities rectangular boxes 5 faces IML labeling top entry IML system installed for production.

FCS Released Its All-Electric Two Components Injection Molding Machine With a Production Demo of Air Tight Container

Chinaplas 2024 -- Lanson Machinery Will Showcase New GE Series All Electric Injection Molding Machine at Booth #2.1F142

Contact SWITEK IML

sales06@switek.biz

+86 186 5927 5869

DongGuan, GuangDong, China

HuangYanZheng©Copy Right