| Description | Unit | Value |

|---|---|---|

| INJECTION UNIT | ||

| Shot volume | cm3 | 1077 |

| Shot weight | g | 0 |

| Shot speed | mm/s | 160 |

| Screw diameter | mm | 70 |

| Injection pressure | MPa | 169 |

| Screw L:D ratio | -- | 25 |

| CLAMPING UNIT | ||

| Clamping force | kN | 3800 |

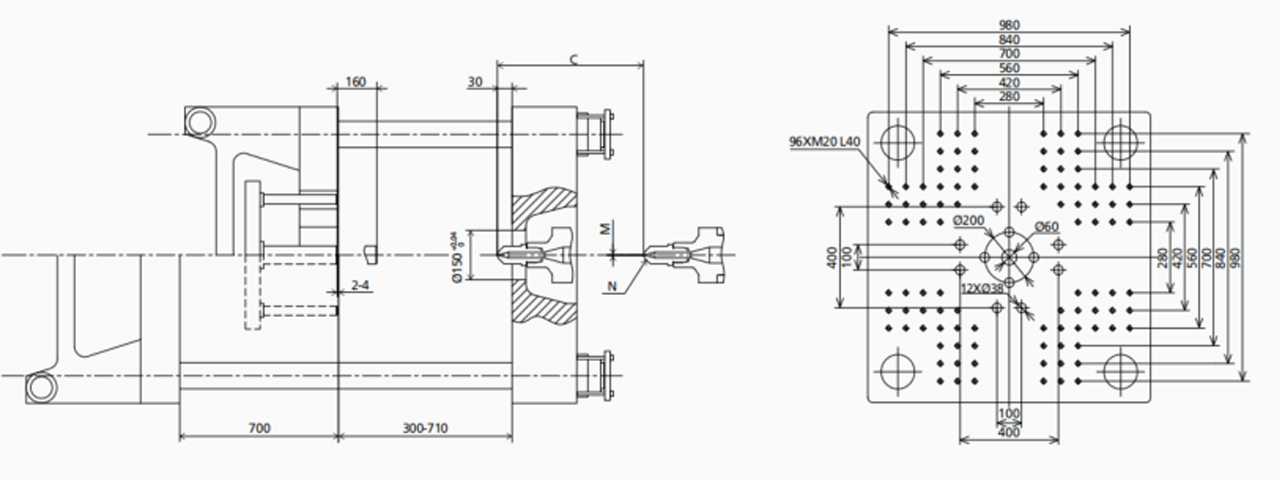

| Opening Stroke | mm | 700 |

| Space between tie bars | mm x mm | 770 x 770 |

| Mold thickness(min) | mm | 300 |

| Mold thickness(max) | mm | 710 |

| Hydraulic ejection stroke | mm | 160 |

| Hydraulic ejection force | kN | 69 |

| POWER UNIT | ||

| Pump motor | kW | 172 |

| Heating capacity | kW | 0 |

| GENERAL | ||

| Oil tank capacity | L | 135 |

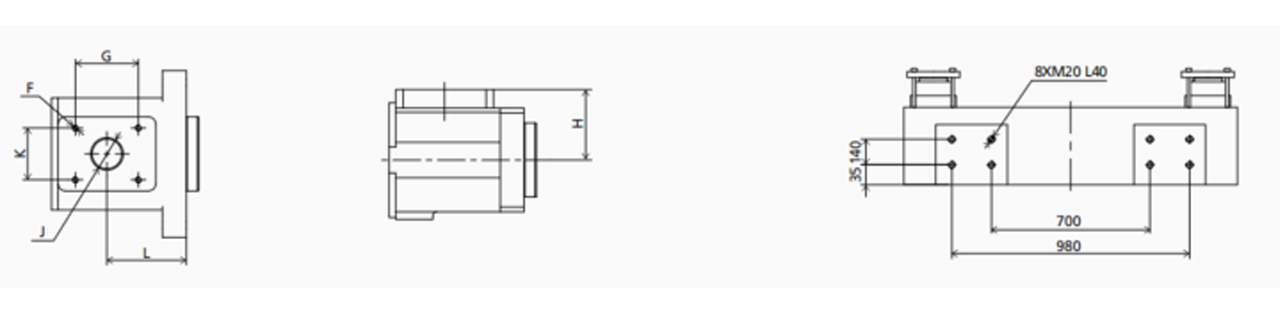

Robot Installation

Platen Dimension

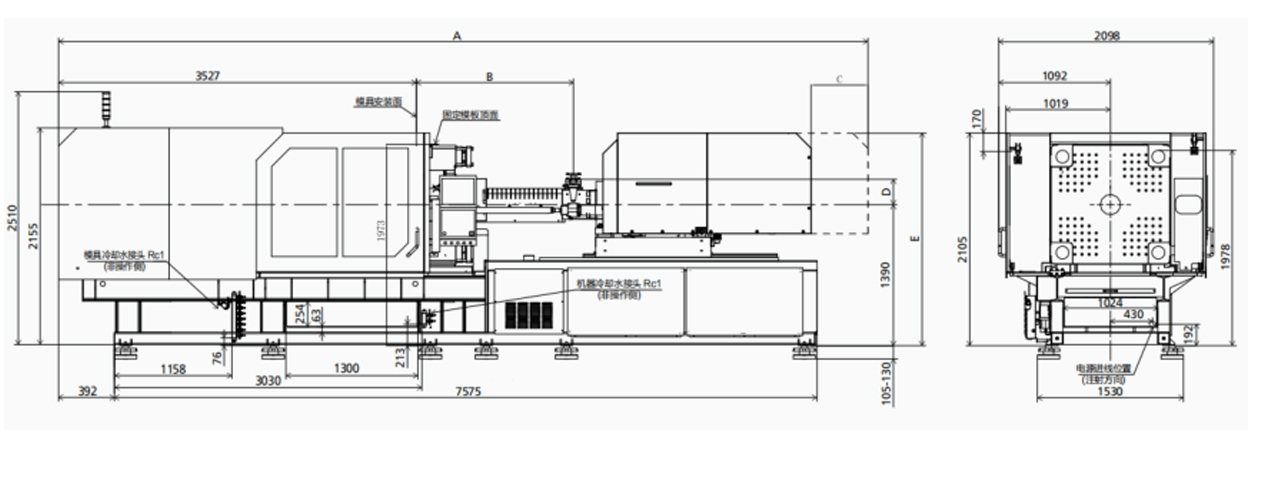

Machine Dimmension

| # | Value |

|---|---|

| A | 8216 mm |

| B | 1754 mm |

| C | 610 mm |

| D | 250 mm |

| E | 2095 mm |

| F | 4 x M10 L20 |

| G | 115 mm |

| H | 148 mm |

| J | φ80 mm |

| K | 115 mm |

| L | 217 mm |

| M | φ4 mm |

| N | SR10 |

BECK Automation turn-key IML solutions for food packages with 6-axis robots cardboard boxes loading solutions released for a biology polution free food package production.

Not only the European food package producer will have the request of cardboard boxes loading, but also their Chinese counter parts. The leading dairy products producer in China like Yili, Mengniu etc. all request their package manufacturers that the packages supplied must be free from bioatic pollution such as hair or finger print. A turn-key IML containers injection production solution with cardboard boxes loading will perfectly solve this problem.

Another package packing solutions would be IML + visual contol + containers bag auto-packing. A packing scheme could be 50pcs or 100pcs optional. It's a popular solution among Chinese dairy products producers as a price smart turn-key food containers IML Production.

Turn-key IML Solutions

Turn-key Pipe Fittings Injection Automation Solutions

Turn-key Cutlery Packing Automation Solutions

High Performance Injection Robot

ไอเอ็มแอล เทคโนโลยี เอ็กซ์เพรส

Arburg Released New Turn-key IML Solutions for Pharmaceutical Tubes IML Solutions

ARGE Declared to Have 6s Top Entry IML Robot for 2 Cavities 2 Litter Pail Buckets

Hwamda Machinery New High Speed Injection Robot HMD 320M8 Started Up in a Pail Production Project

Welltec Machinery Demonstrated Their High Speed Injection Molding Machine on An 8 Cavities Yogurt Cups IML Production

A New Forza Series Two Platen Injection Molding Machine by Ningbo LK Technology Co., Ltd. Was Installed for the Production of Plastic Chairs.

K-Fair 2022, NESSI & NEGRIBOSSI had a Joint Exhibition Show

ENGEL All Electric Injection Molding Machine E-Motion 280T With IML System

Lisong Machinery Tested Their High Speed Hydraulic Injection Molding Machine with a 20L Bucket Mould

NPE 2024 -- Haitian On Show 5th Generation of Jupiter Series Two Platens Injection Molding Machine

Chinaplas 2023 | YanHign Group Will Onshow Their New Hybrid Tow-platen Injection Moulding Machine

Contact SWITEK IML

sales06@switek.biz

+86 186 5927 5869

DongGuan, GuangDong, China

HuangYanZheng©Copy Right