sales06@switek.biz

+86 186 5927 5869

sales06@switek.biz

+86 186 5927 5869

| 설명 | 단위 | 값 |

|---|---|---|

| 주입 장치 | ||

| 샷 볼륨 | cm3 | 2354 |

| 샷 무게 | g | 2142 |

| 샷 속도 | mm/s | 636 |

| 나사 직경 | mm | 90 |

| 사출압력 | MPa | 126 |

| 나사 L:D 비율 | -- | 17.8 |

| 클램핑 유닛 | ||

| 클램핑 력 | kN | 6500 |

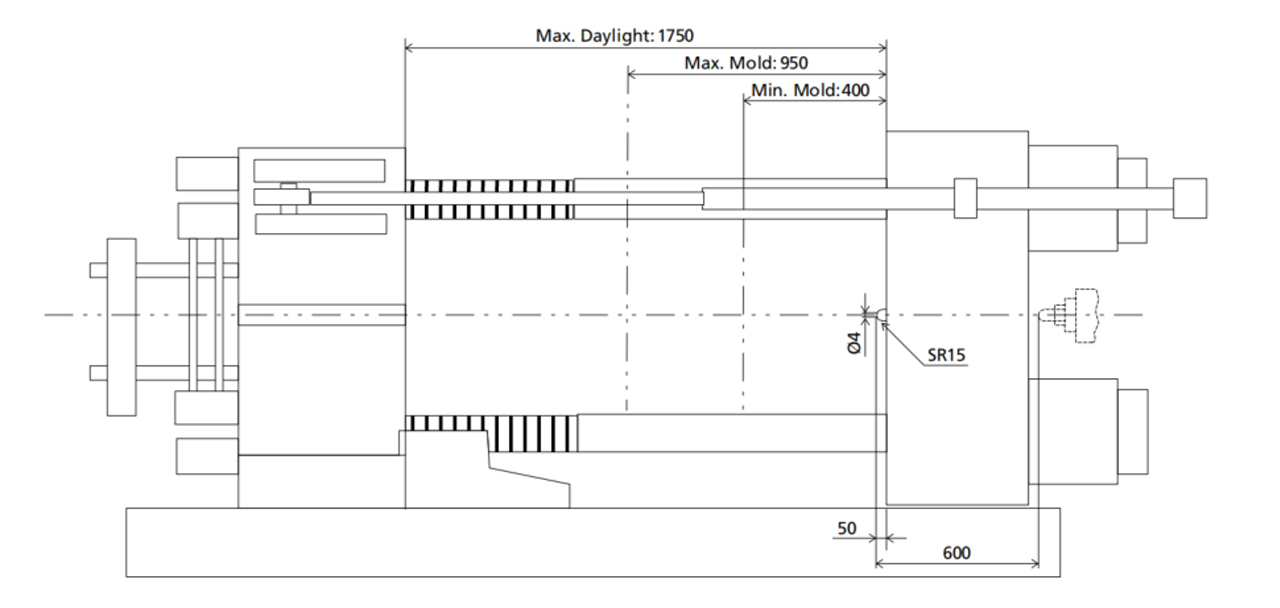

| 오프닝 스트로크 | mm | 1350 |

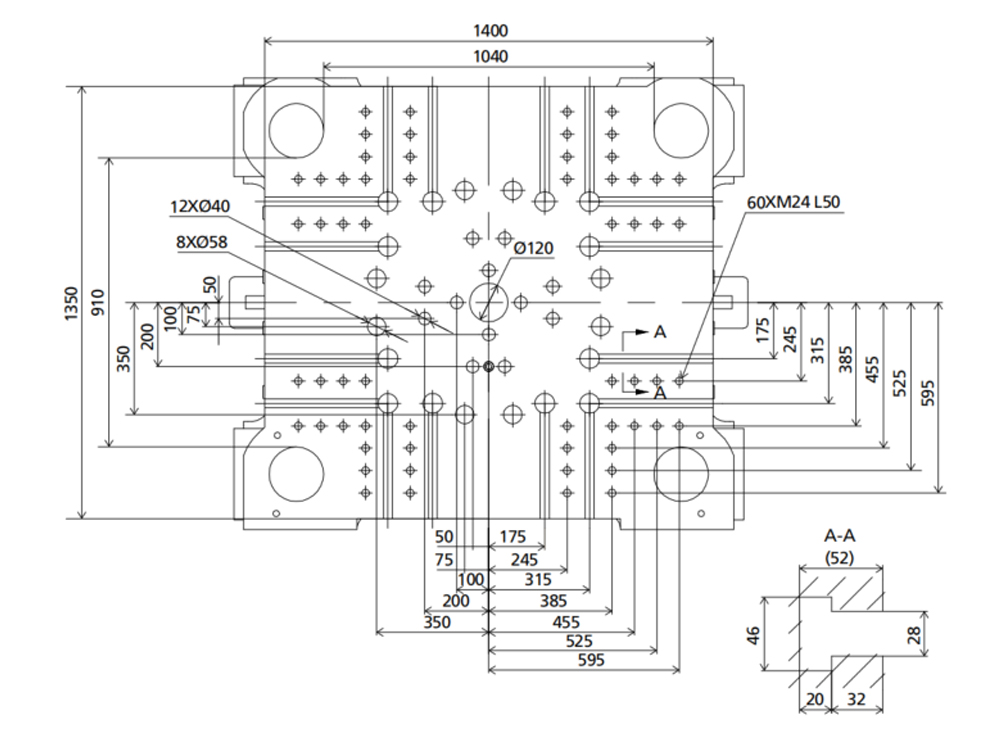

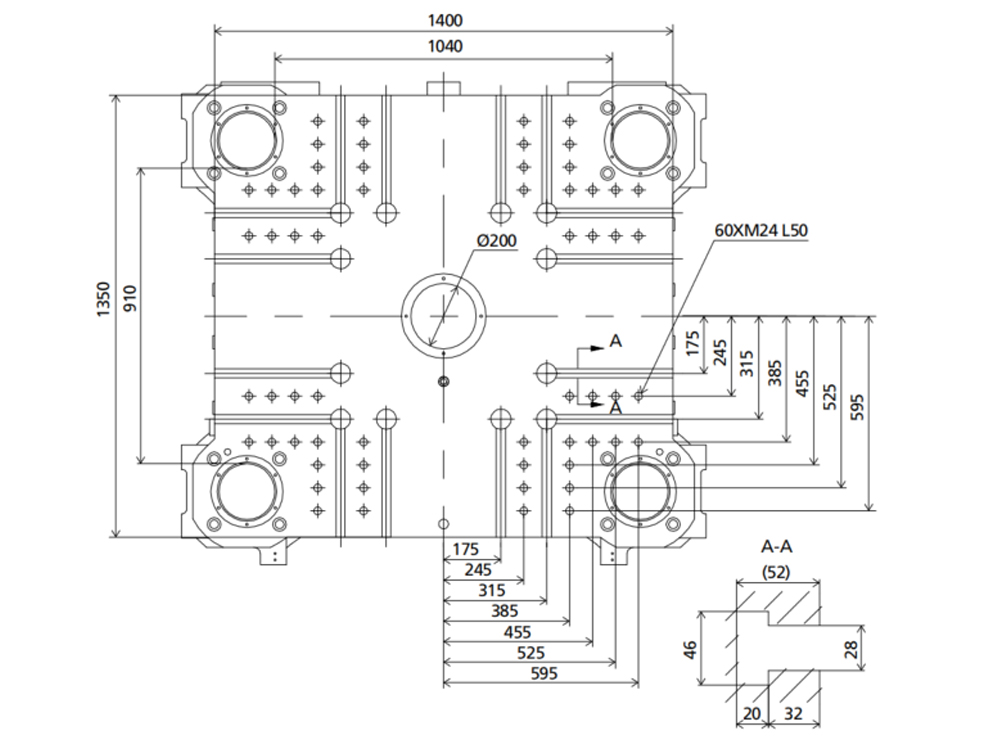

| 타이바 사이의 공간 | mm x mm | 1040 x 910 |

| 금형 두께(min) | mm | 400 |

| 금형 두께(max) | mm | 950 |

| 유압 배출 스트로크 | mm | 250 |

| 유압 방출력 | kN | 110 |

| 전원 장치 | ||

| 펌프 모터 | kW | 55 |

| 난방능력 | kW | 39 |

| 일반적인 | ||

| 오일탱크 용량 | L | 520 |

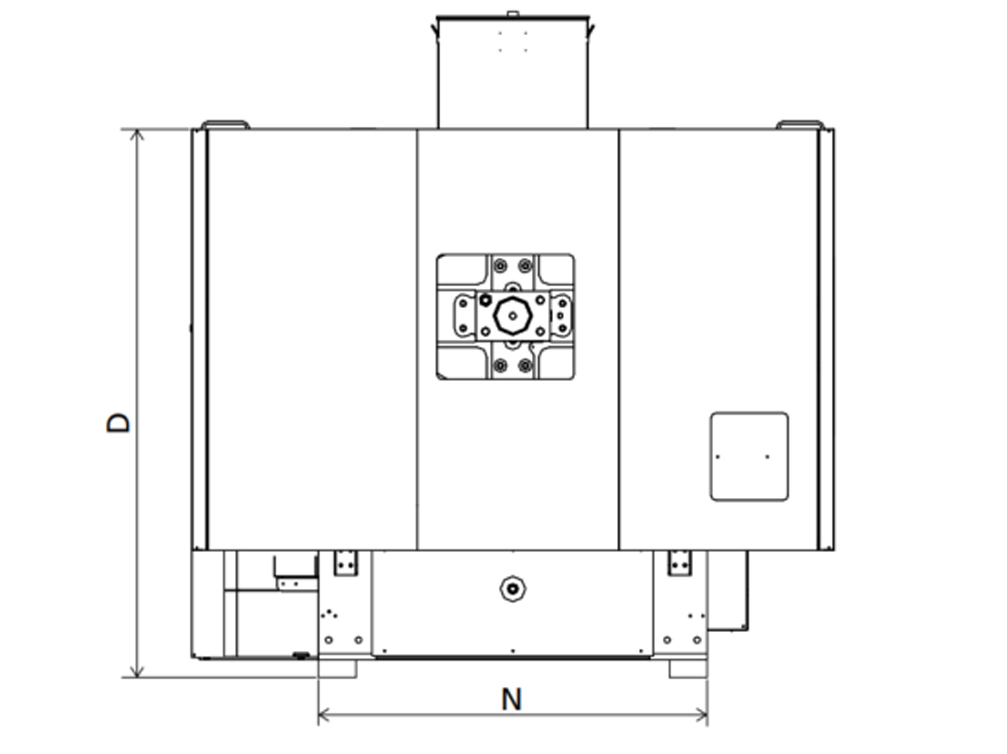

Clamping Unit

Platen Dimensions

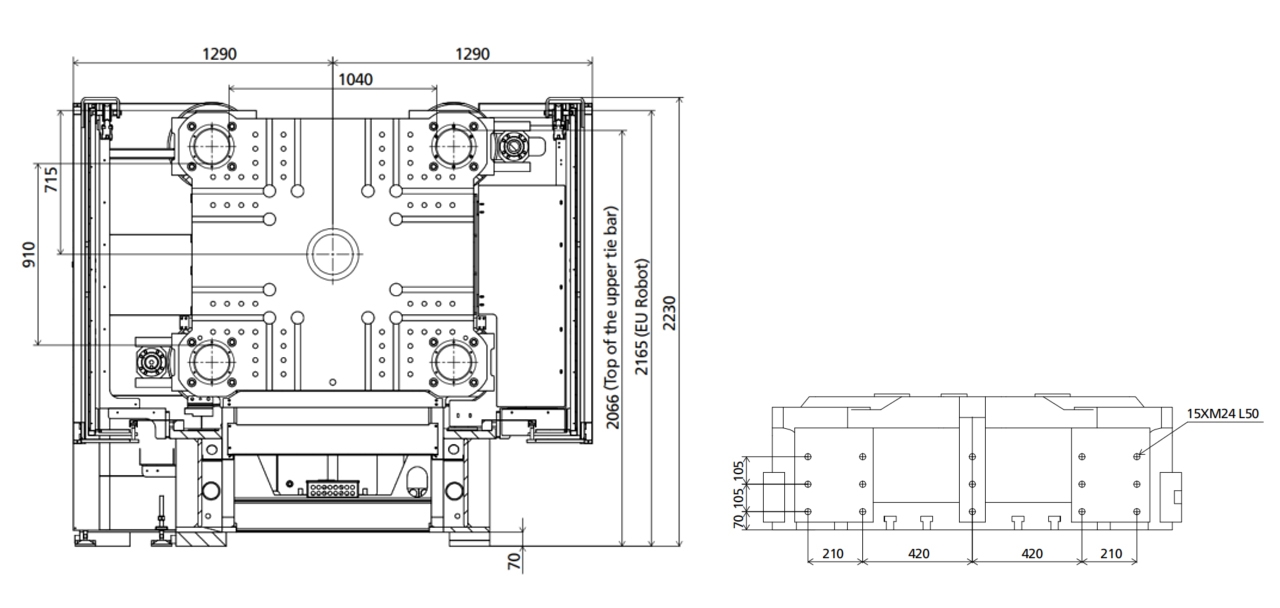

Robot

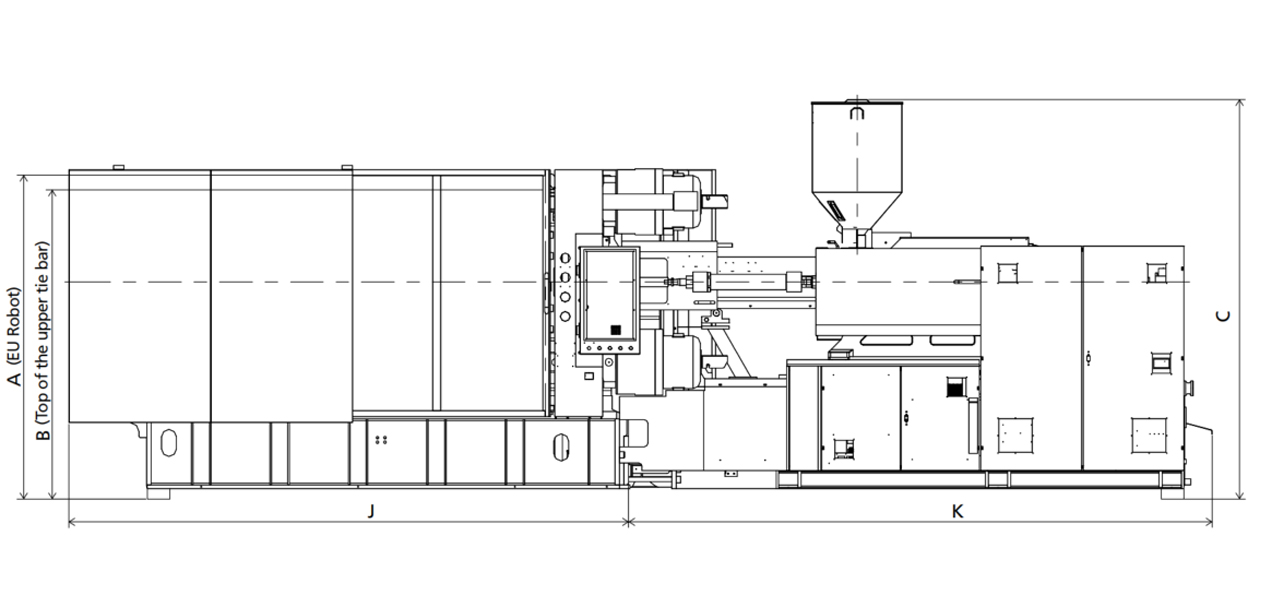

Front View

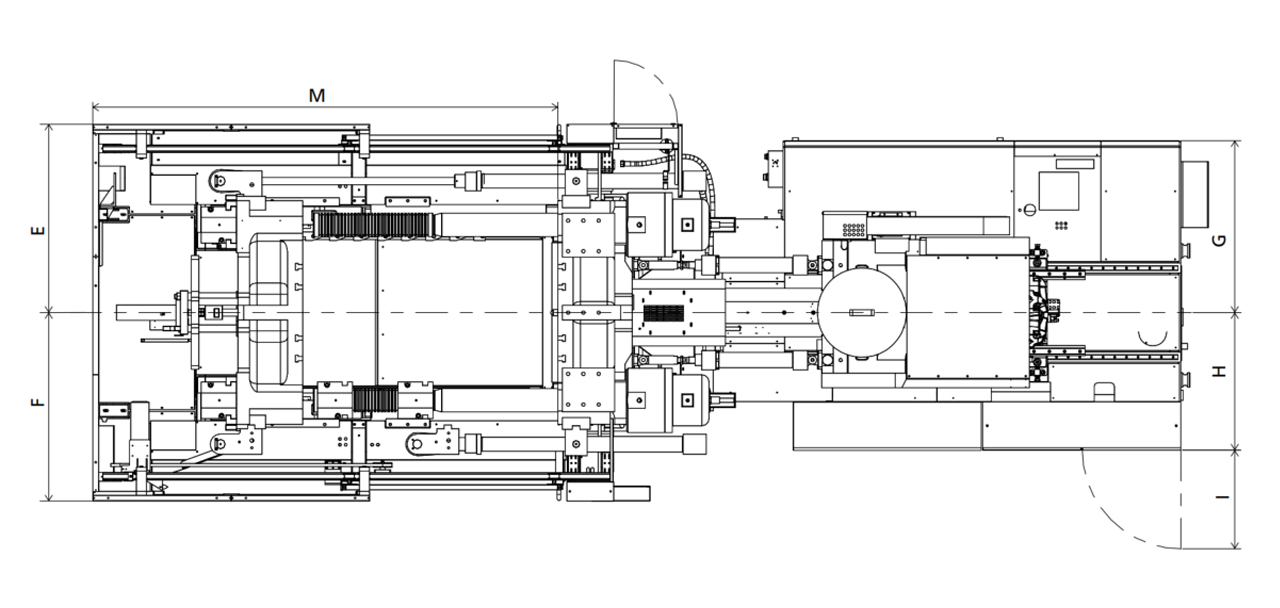

Top View

Side View

| # | Value |

|---|---|

| A | 2165 mm |

| B | 2066 mm |

| C | 2366 mm |

| D | 2200 mm |

| E | 1290 mm |

| F | 1290 |

| G | 1082 mm |

| H | 903 mm |

| I | 675 mm |

| J | 3746 mm |

| K | 3722 mm |

| M | 3191 mm |

| N | 1560 |

What's the High Speed 3 Axis Servo Injection Robot to be Recommended for Zhafir VE3600II

뜨거운 주입 자동화 뉴스

E-mail: sales@switek.biz

블로거에게 연락하기

sales06@switek.biz

+86 186 5927 5869

DongGuan, GuangDong, China

자동화 솔루션